Inwestycja w robotyzację produkcji – korzyści finansowe, trendy, wyzwania

Zgodnie z opublikowanym w 2020 roku raporcie Międzynarodowej Federacji Robotyki (IFR), populacja sprzedanych na świecie robotów stale rośnie.

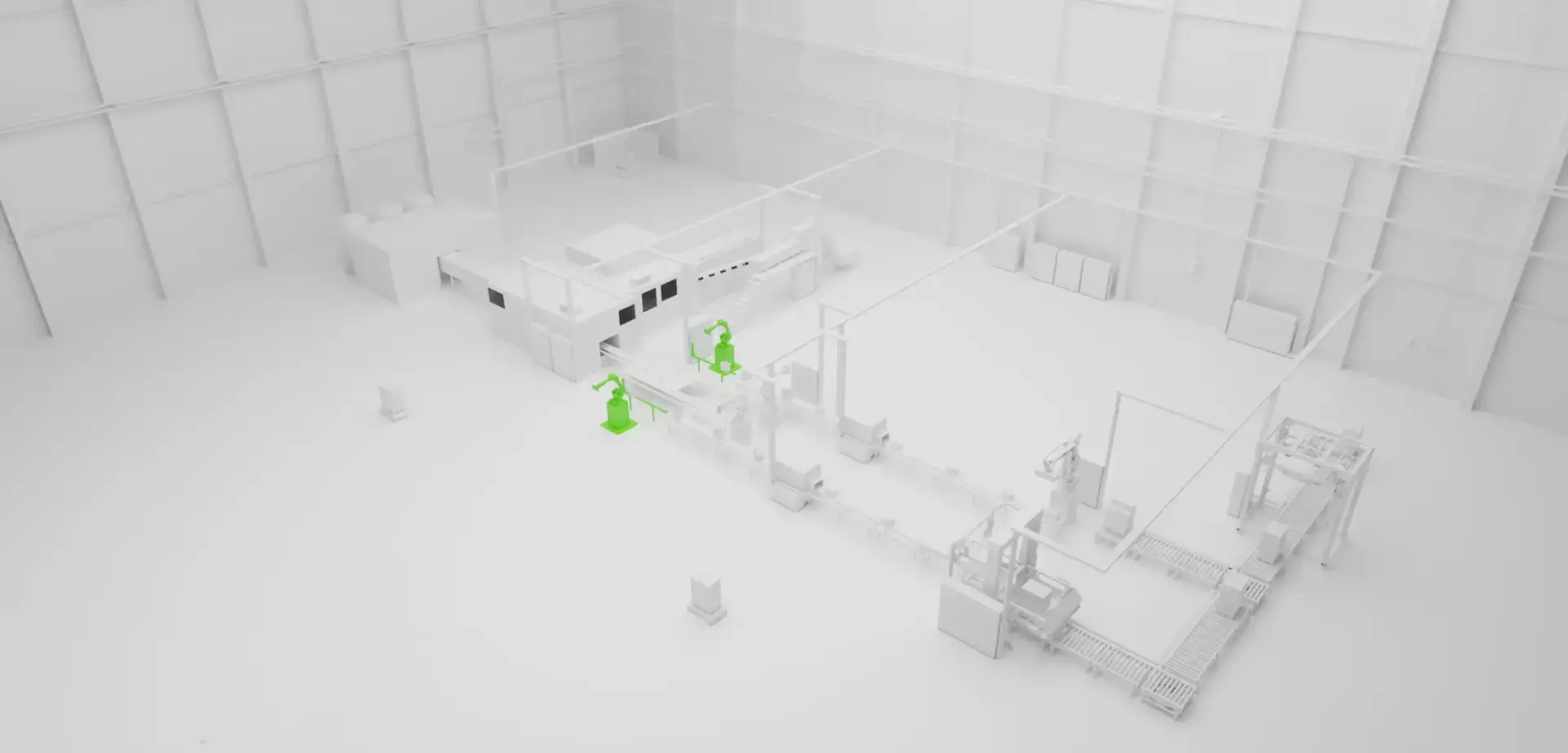

From analysing your production situation, through developing concepts and optimising costs, to implementing solutions improving the production. Comprehensively. Proster.

ConsultationSprawdź co oferujemy w Automatyzacji Linii Produkcyjnych ⬇

Our long-standing presence in the industry has allowed us to learn the problems and expectations of our customers. Therefore, we have been able to develop proven solutions, but we will always adapt them to the specifics of your production. We understand that you may face challenges such as:

Without knowing the robotics and automation industry from the design and implementation side, it is difficult to even estimate the budget. And its optimisation in this case is impossible.

You are wondering if your production is prepared at all for robotics or automation. You would like to get an expert opinion and expert advice on this issue.

Automation does not tolerate lack of repetition and quality deficiencies. But which parameters are most important and how should they be improved?

Some employees fear losing their jobs as a result of being replaced by robots. Others doubt whether they can handle modern, computerised equipment.

Are you confident that your production is prepared for robotics or automation? Or do you lack trained employees or details of expected changes?

The use of automation requires preparation, the implementation of which may stretch out for reasons beyond your control. And yet every delay affects subsequent processes.

We recognise your needs to offer a solution tailored to your expectations. This allows us to optimise costs and help you prepare your budget.

We provide feedback on imperfections in your preparation or processes, which we will remove together to make robotisation or automation possible.

We will point out to you exactly which production parameters should be improved and how.

We fit in with your deadlines. We are flexible, so we can adjust the project’s delivery and launch dates to fit your time frame.

We’ll give you tips on how to increase employee awareness, broaden the staff’s skills or provide a different workplace.

We are not limited by industries, as we have proven packaging and palletising solutions in many sectors. But the most common use of robotics and production automation is in the industry of:

01

Food

02

Plastics processing

03

Foundry

04

Construction

Send an inquiry or call +48 693 653 035. We will talk for a few minutes about the challenges you face.

See case studies of customers who have trusted us.

Long-term cooperation with our Customres often begins with professional advice from our experts.

50+

consulting audits carried out

100+

concepts made for customers

Developing a solution tailored to the customer's needs is a challenge we must meet in 100%.

5+

developed machine designs

10+

implemented projects of robotic lines and stations

Proster's large team of skilled professionals will seamlessly execute even a particularly complex project.

60+

employees can be involved in the project

25+

million PLN is the total cost of the projects we have implemented

It all depends on the number of robots used for the solution, the processes we want to robotise, the performance of the target workstation and the production parameters. Smaller stations can cost as little as a few hundred thousand PLN, and larger ones can cost up to a dozen/ten million PLN. If you would like an approximate budget cost, please contact us.

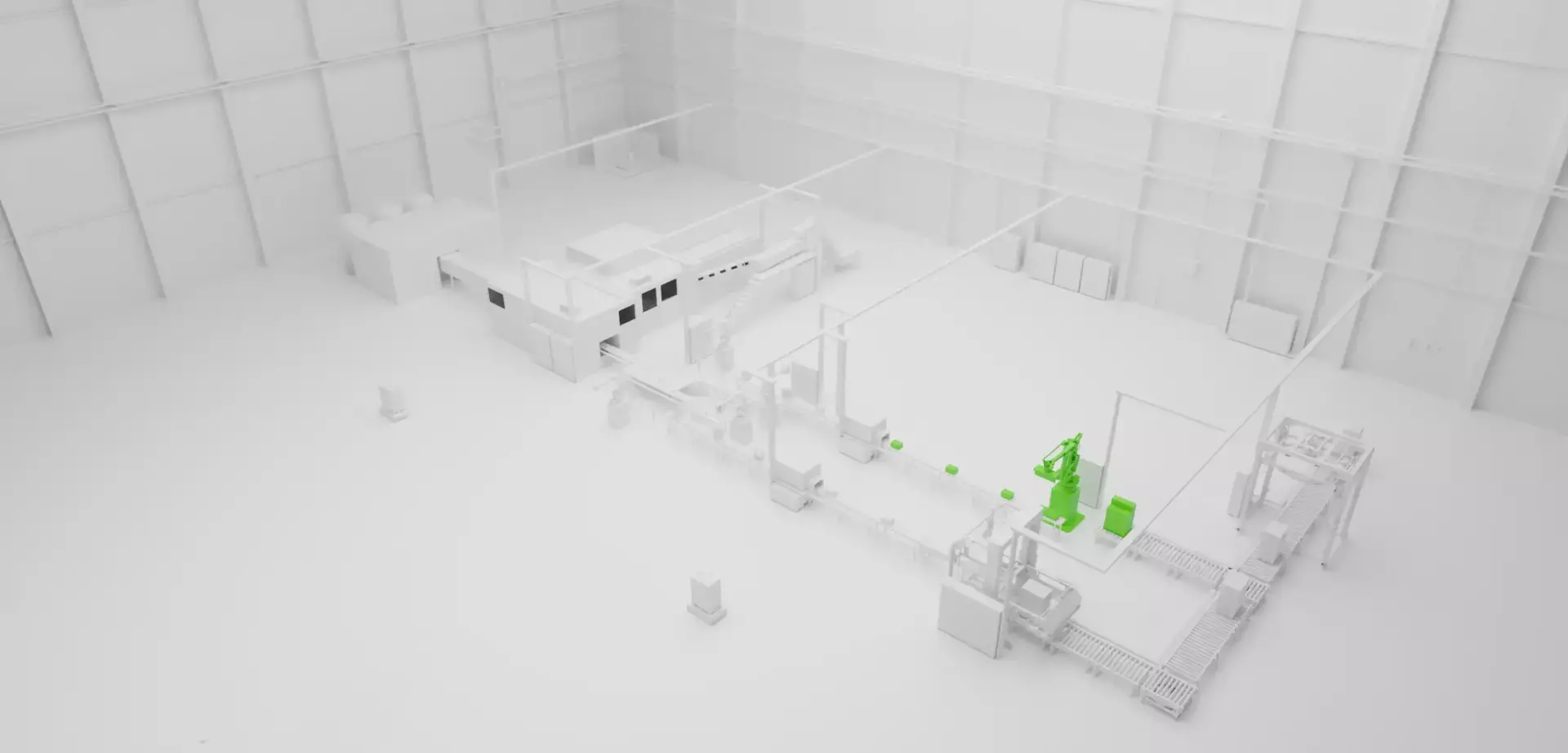

On each project we are able, in consultation with the customer, to simulate the degrees of efficiency improvement after the project is completed. From our experience, we are aware that the introduction of just 2 new robots can generate productivity increases of up to 300%.

The use of a robot does not completely eliminate human labour, while it significantly reduces their participation in production, allowing to reduce also accidents at work or downtime due to, for example, sick leave. This means that people previously working in production can be delegated to other tasks.

Before starting the project, we can perform an audit for you of the place where you want to make changes and help you prepare it for production process.

We have completed more than 5,200 projects for customers around the world for more than a dozen industries, which can attest to our professional approach also in terms of timeliness. In addition, we have every performance date written into the contract.

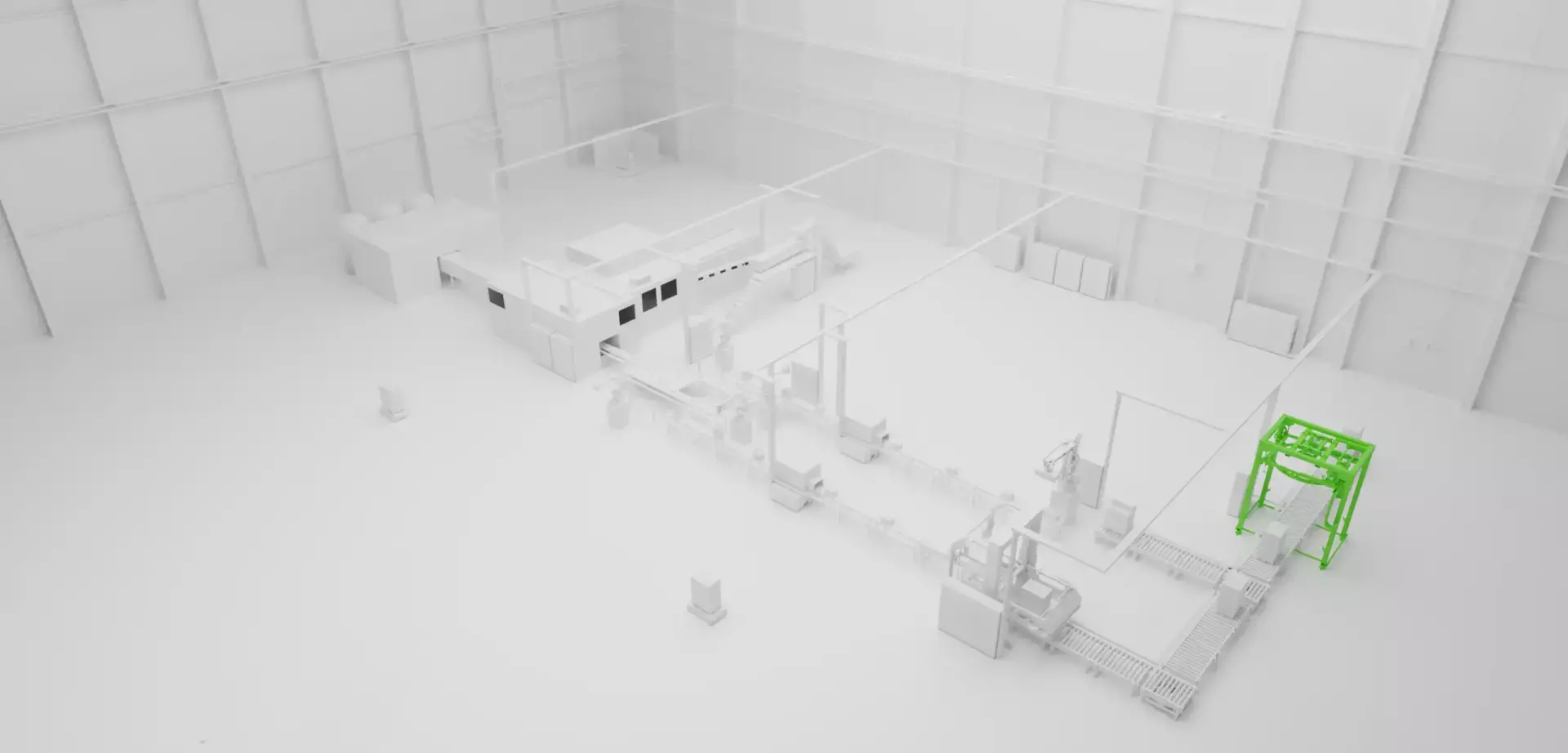

Despite the popularity of robots, they are complex devices that come at a price. In addition to it, the cost of designing and manufacturing a suitable gripper, as well as the time needed to assemble and commission the station should also be included in the calculation.

It all depends on the number of robots used for the solution, the processes we want to robotise, the performance of the target workstation and the production parameters. Smaller stations can cost as little as a few hundred thousand PLN, and larger ones can cost up to a dozen/ten million PLN. If you would like an approximate budget cost, please contact us.

The use of a robot does not completely eliminate human labour, while it significantly reduces their participation in production, allowing to reduce also accidents at work or downtime due to, for example, sick leave. This means that people previously working in production can be delegated to other tasks.

We have completed more than 5,200 projects for customers around the world for more than a dozen industries, which can attest to our professional approach also in terms of timeliness. In addition, we have every performance date written into the contract.

On each project we are able, in consultation with the customer, to simulate the degrees of efficiency improvement after the project is completed. From our experience, we are aware that the introduction of just 2 new robots can generate productivity increases of up to 300%.

Before starting the project, we can perform an audit for you of the place where you want to make changes and help you prepare it for production process.

Despite the popularity of robots, they are complex devices that come at a price. In addition to it, the cost of designing and manufacturing a suitable gripper, as well as the time needed to assemble and commission the station should also be included in the calculation.

Inżynier Sprzedaży

Even if they are not yet fully specified.

Automatyzacja produkcji to proces wykorzystania zaawansowanych technologii do optymalizacji procesów wytwórczych. Dla firm produkcyjnych oznacza to rewolucję w sposobie funkcjonowania. Inwestycja w automatyzację to krok w przyszłość dla firm produkcyjnych. To nie tylko zwiększenie konkurencyjności, ale także otwarcie na nowe możliwości rozwoju i innowacji.

Firmy produkcyjne mogą bardzo dużo zyskać inwestując w automatyzację produkcji. Oferuje ona bowiem szereg korzyści, polepszających wyniki przedsiębiorstwa na wielu płaszczyznach.

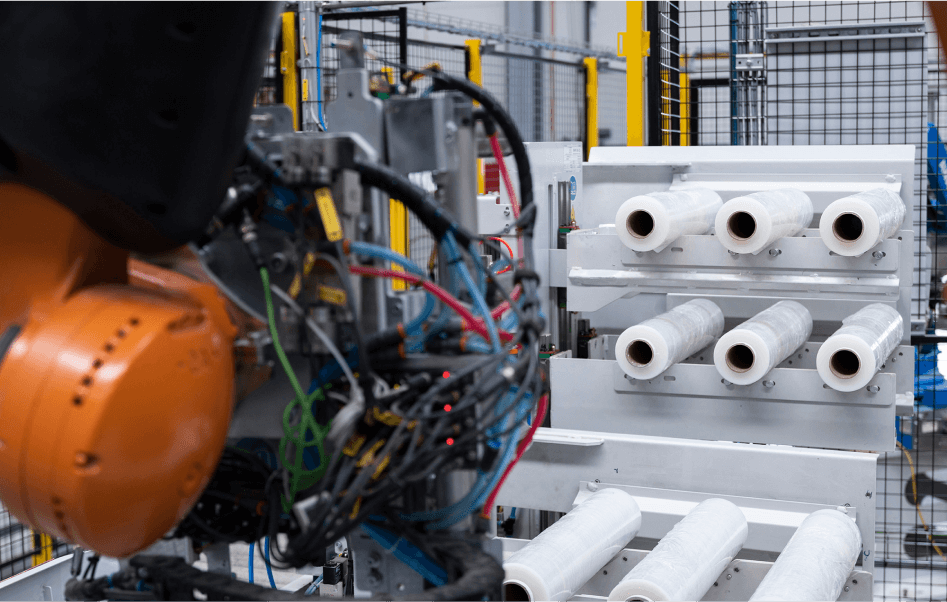

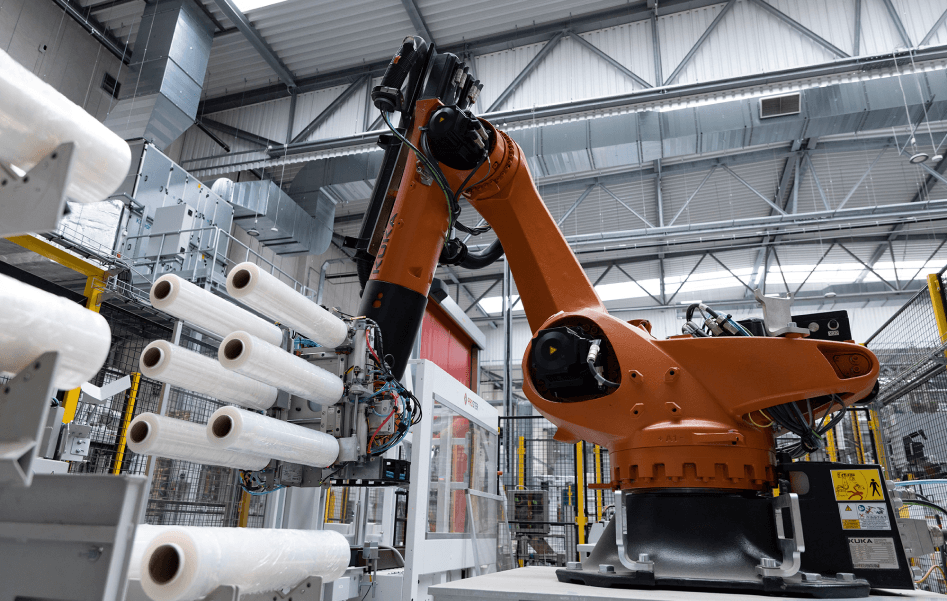

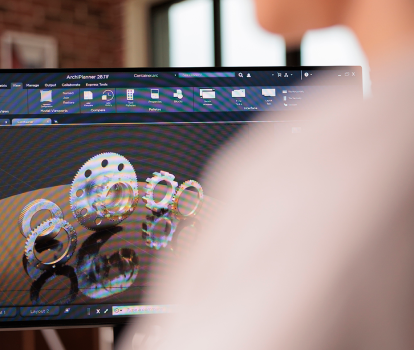

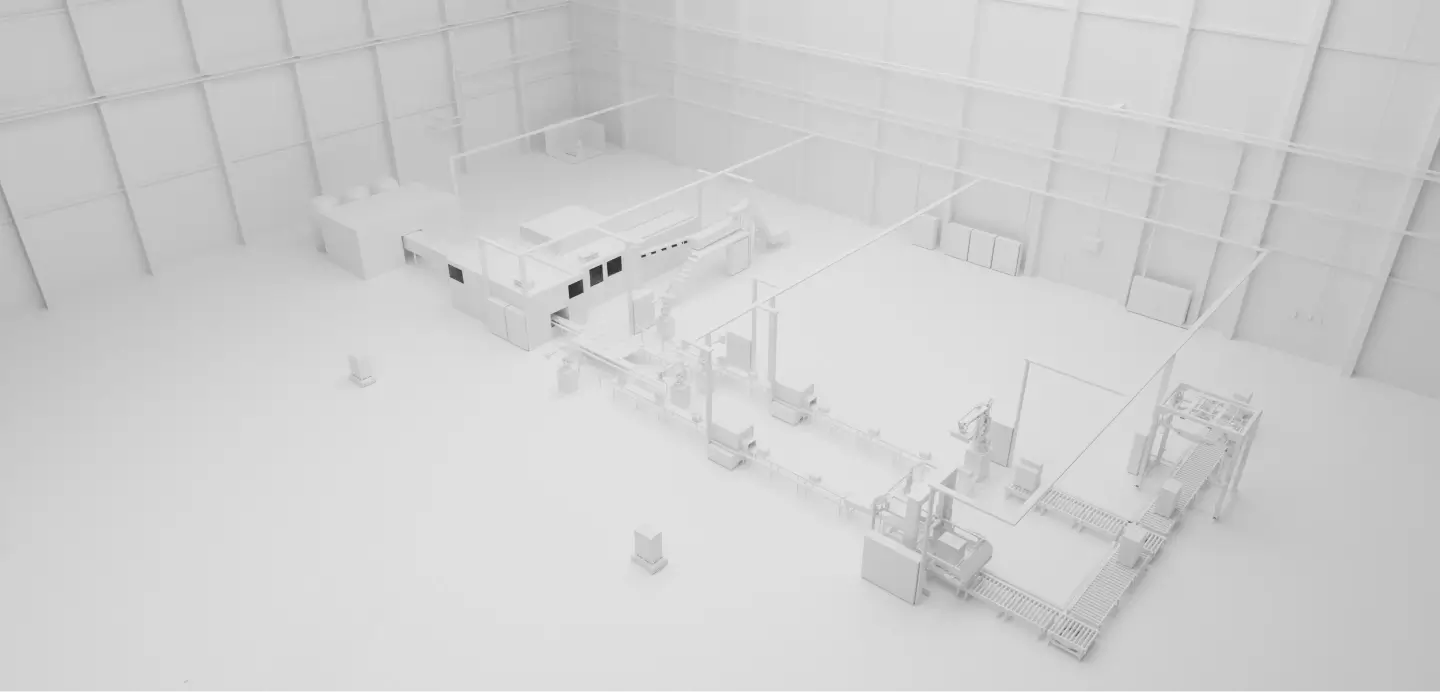

Automatyzacja produkcji to nie tylko maszyny i urządzenia, ale również oprogramowanie służące do monitorowania, analizy i zarządzania procesami przedsiębiorstwa. Przykładami maszyn i systemów automatyzacji są maszyny technologiczne dla rożnych branż i produktów (np. rozlewnice, wydmuchiwarki butelek), maszyny do automatycznego pakowania, foliarki, roboty przemysłowe, coboty, roboty kartezjańskie, przenośniki produktu, opakowań i palet, paletyzatory, owijarki do palet, roboty mobilne AMR, AGV, automatyczne regały magazynowe, systemy SCADA, ERP, MES, CMMS, itp.

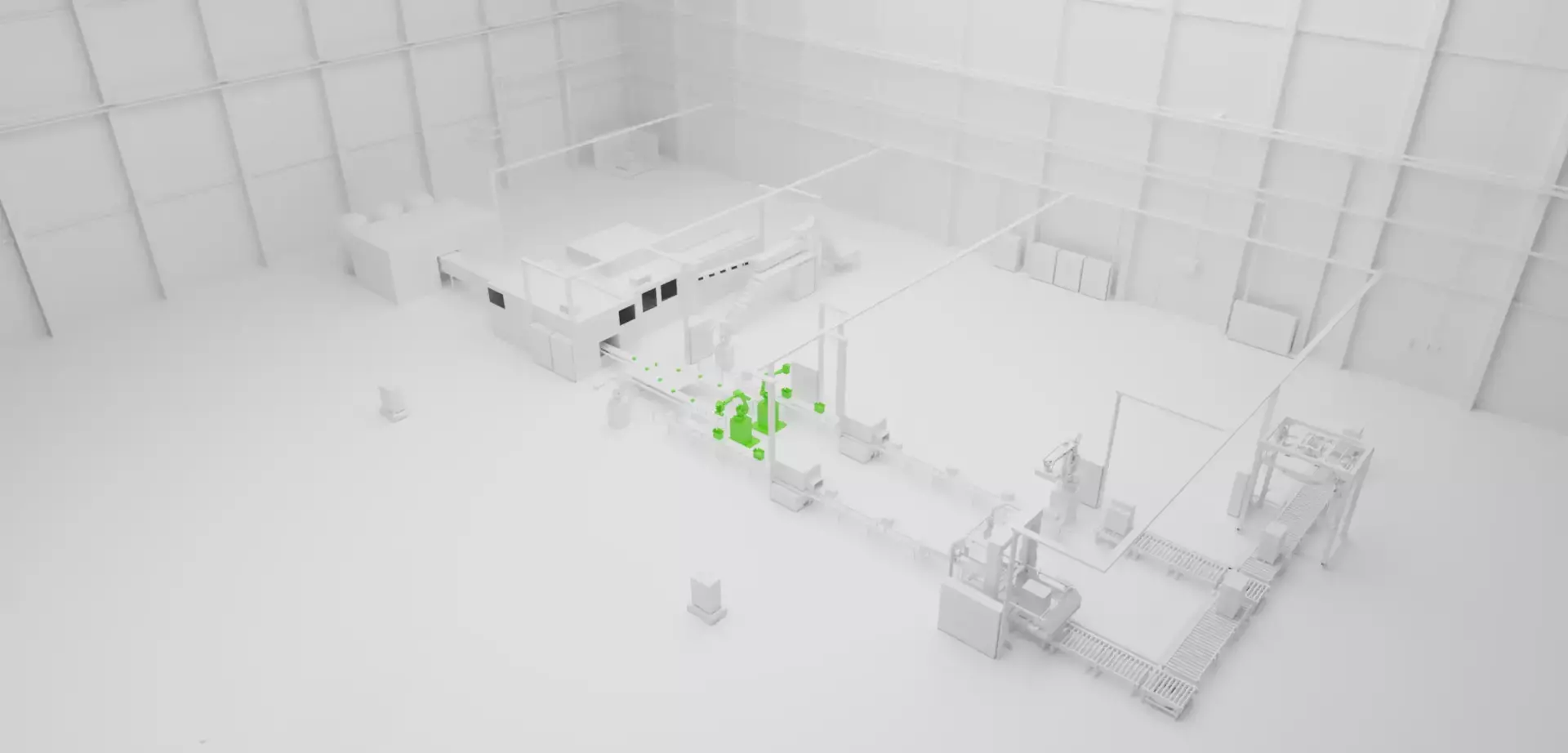

Robotyzacja produkcji to bardzo ważny element nowoczesnej automatyzacji. Roboty przemysłowe (w tym coboty) oferują niezrównane połączenie precyzji, wydajności i elastyczności. Precyzji, ponieważ ich dokładność sięga setnych części milimetra. Wydajności, ponieważ potrafią realizować zadania naprawdę bardzo szybko. Również elastyczności, ze względu na ich możliwości dostosowania się do różnych zadań produkcyjnych czy wielu produktów.

Montaż, spawanie, przenoszenie, obsługa maszyn cnc, pakowanie i paletyzacja, czy kontrola jakości to niektóre z zadań, jakie mogą pełnić. Ważną korzyścią z ich zastosowania jest obsługa niebezpiecznych lub obciążających dla człowieka czynności.

Wdrożenie robotyzacji to strategiczna inwestycja w przyszłość firmy produkcyjnej. To nie tylko zwiększenie efektywności, ale także krok w kierunku Przemysłu 4.0, gdzie inteligentne, połączone systemy definiują nowe standardy produkcji.

Dobrym początkiem wdrażania automatyzacji będzie analiza obecnej sytuacji na produkcji. Poznanie procesów, które funkcjonują wystarczająco efektywnie, ale przede wszystkim tych, wymagających poprawy jest niezbędne na start. Pozwala zidentyfikować miejsca do poprawy lub wyeliminowania zbędnych kroków jeszcze przed automatyzacją. Istotne jest także poznanie rozwiązań technologicznych, które są oferowane na rynku. Dowiemy się dzięki temu, jakie procesy są w ogóle możliwe do automatyzacji, jakie są wskaźniki skutecznego wdrożenia, a przede wszystkim zmniejszymy ryzyko nierentowności inwestycji.