Popraw wydajność produkcji dzięki robotyzacji

Zminimalizuj uzależnienie produkcji od kompetencji pracowników i skup się na doskonaleniu produktu, a nie ciągłych problemach produkcyjnych.

Comprehensive work carried out entirely by our specialists. On schedule and on budget. By the deadline or even earlier.

ConsultationSprawdź co oferujemy dla produkcji i przemysłu, producentów maszyn, generalnych wykonawców oraz logistyki i dystrybucji ⬇

39 years in the industry is a long time to get to know the challenges our customers face. We understand that your problem may be:

We know how difficult it is to find specialists for installation of production lines, because we have spent many years building a team of experts in this field ourselves.

One installation team at your company is not enough for multiple locations. Cost of maintaining multiple teams is too high.

It can be sometimes way too expensive to carry out such projects alone.

Downtime and unexpected problems can significantly increase the cost of the entire project.

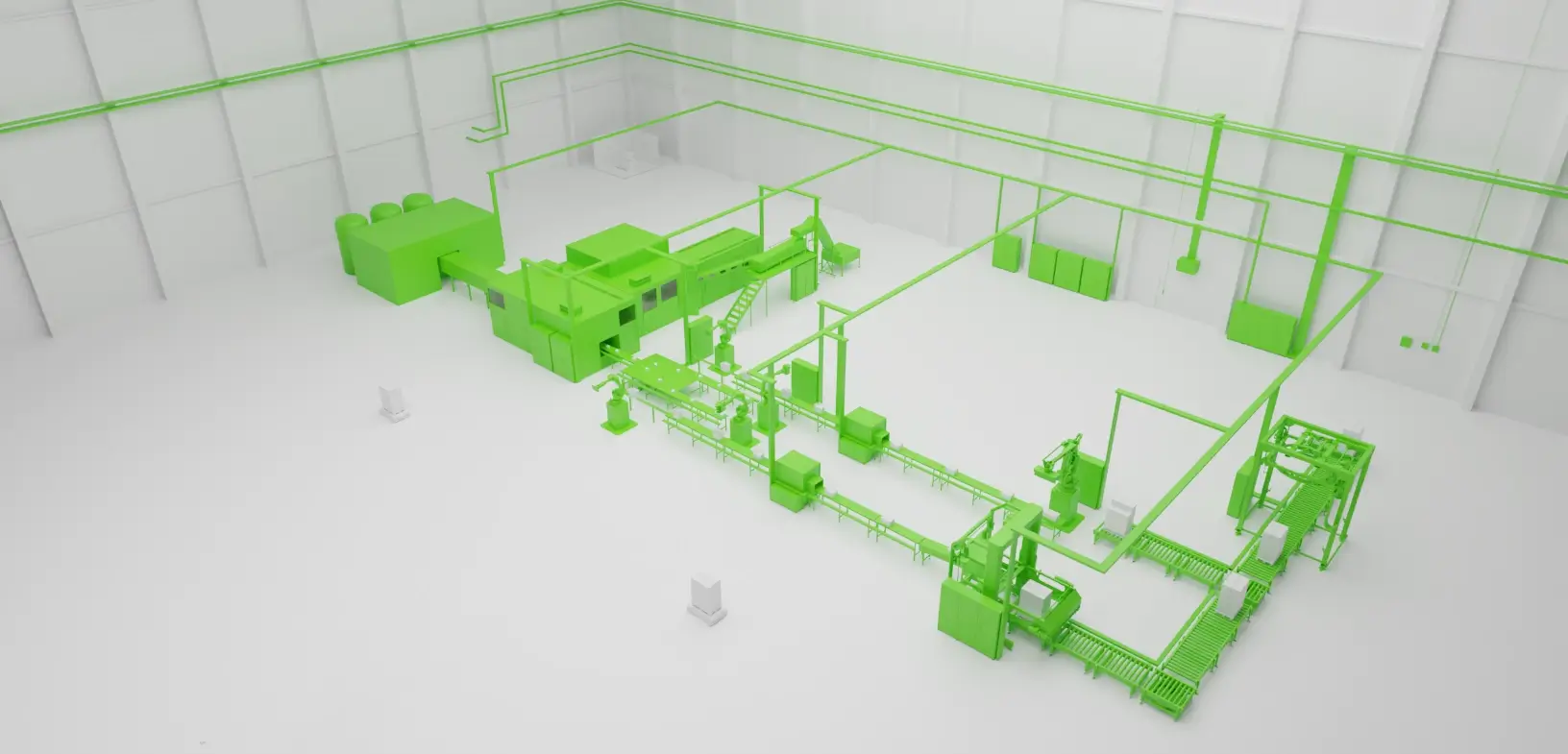

A new or retrofitted production line should significantly increase your company's capabilities.

Emerging changes in the project require flexibility from the contractor.

We have created a team of specialists who have been meeting the goals of our customers for years. These experts have the knowledge, experience and motivation. But tapping into their potential will always prove financially more advantageous than doing the project yourself.

Our goal is to meet the expectations of

not only you, but also your customers, so our projects always enhance your company’s capabilities.

We will assemble or retrofit a production line on any continent, regardless of the number of sites. Always in accordance with the budget, agreed at the beginning of the cooperation.

Our employees are experienced experts whose qualifications we continue to improve through industry training and courses. Professional contractors are guaranteed to complete your project.

In our nearly four decades of presence in the industry, we have completed projects in many locations around the world. Our installation teams are at your service regardless of the location of your company sites.

We assemble and retrofit production lines for many sectors of the industry. Most often it includes industries such as:

01

Food

02

Automotive

03

Power engineering

04

Construction

05

Pharmaceuticals

06

Wood

Send an inquiry or call +48 693 653 035. We will talk for a few minutes about the challenges you face.

The scope of our work is the comprehensive implementation of your order. Therefore, our cooperation will provide you with many benefits.

Each of our projects comes with a warranty, which can be extended during the post-warranty period.

We use only modern technology and the most efficient components from leading manufacturers from around the world.

We have been in the industry for nearly four decades. And we would like to work with you in the years to come.

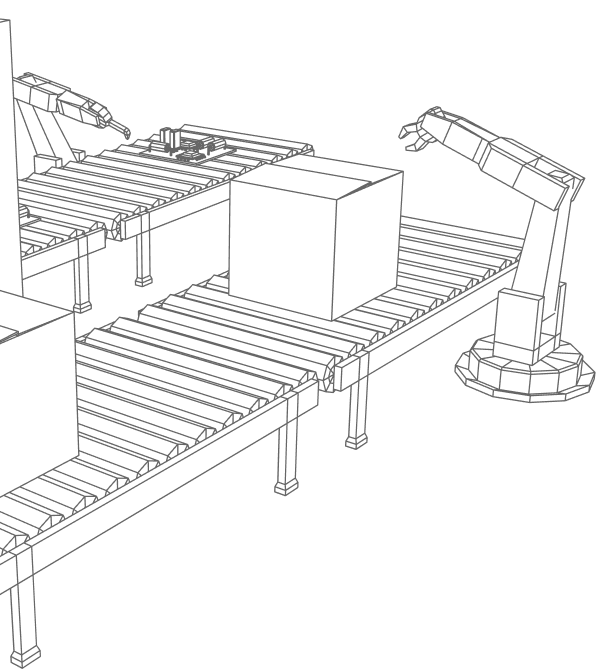

Installing new or upgrading existing production lines enable you to increase or optimise the production.

An investment in increasing the capacity and quality of production, is an investment in the modernity of your company.

In our implementations, the realisation of higher standards goes hand in hand with increased safety for your employees.

See case studies of customers who have trusted us.

The smooth implementation of such large projects requires well considered workflows. Here is our way of doing things, perfected over the years and proven in practice.

1

We carefully review the details of your challenge.

2

Always includes all and total costs.

3

Formally begins our cooperation

4

On time and always on budget.

5

You can still benefit from our support.

Yes, our employees have the appropriate training and qualifications to perform this type of work. In addition, the average length of work with us is 8 years, which makes them well trained and they have already done dozens of projects with us.

We are a company from Małopolska region, not only have we implemented projects in every voivodeship in Poland, but also thousands of projects abroad, including in Japan, China, Brazil and New Zealand.

Yes, in the offer we provide a proposal with a detailed quote for the work to be commissioned. We have the option to work on a pre-agreed amount or a rate per hour of work.

The new production line can significantly improve production efficiency rates, productivity, quality of end products and minimise downtime.

We are a family-owned company with the advantage of being able to respond relatively quickly to project changes as they occur. Therefore, minor modifications during the course of the work can be implemented quickly.

We have up-to-date Occupational Health and Safety training, regularly use the services of a Health and Safety Inspector, and have the right equipment to provide you with the best solutions in this area.

No, each project is handled by us - PROSTER. Occasionally, we use subcontractors that have proven themselves over many years.

Yes, our employees have the appropriate training and qualifications to perform this type of work. In addition, the average length of work with us is 8 years, which makes them well trained and they have already done dozens of projects with us.

Yes, in the offer we provide a proposal with a detailed quote for the work to be commissioned. We have the option to work on a pre-agreed amount or a rate per hour of work.

We are a family-owned company with the advantage of being able to respond relatively quickly to project changes as they occur. Therefore, minor modifications during the course of the work can be implemented quickly.

No, each project is handled by us - PROSTER. Occasionally, we use subcontractors that have proven themselves over many years.

We are a company from Małopolska region, not only have we implemented projects in every voivodeship in Poland, but also thousands of projects abroad, including in Japan, China, Brazil and New Zealand.

The new production line can significantly improve production efficiency rates, productivity, quality of end products and minimise downtime.

We have up-to-date Occupational Health and Safety training, regularly use the services of a Health and Safety Inspector, and have the right equipment to provide you with the best solutions in this area.

Inżynier Sprzedaży

Even if they are not yet fully specified.