Proster członkiem FAIRP – Forum Automatyki i Robotyki Polskiej

Nasze członkostwo w FAIRP jest wyraźnym sygnałem dla naszych partnerów biznesowych, że angażujemy się w rozwój nowoczesnych metod […]

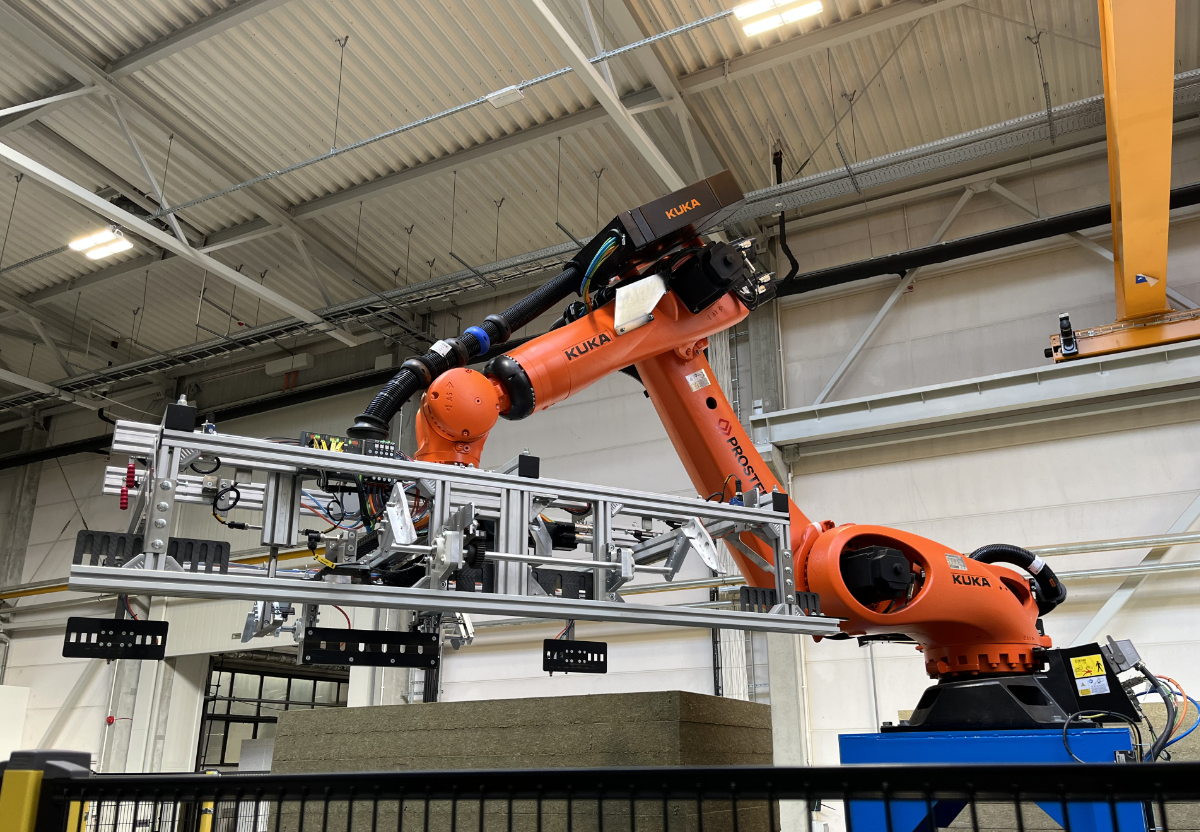

The use of a robot in palletising and depalletising processes significantly increases efficiency and precision, as well as improving the quality and streamlining the distribution of pallets with goods.

ConsultationOur long-standing presence in the industry has allowed us to learn the problems and expectations of our customers. We understand that you may face challenges such as:

This is a standard challenge of every robotics project. However, the processes around palletising or depalletising need to be refined for this relationship to be sustainable.

Enterprises constantly strive to reduce production costs. Increasing the efficiency of a company's operations and improving its profitability is quite a challenge.

Customers often need quick access to real-time data. Making optimal decisions must be supported by them.

Fewer and fewer employees want to work in production - this is a big challenge that can be directly reduced by robotization.

Paletyzacja i depaletyzacja są procesami, które odgrywają znaczącą rolę w wielu firmach produkcyjnych i dystrybucyjnych, zwłaszcza tych przetwarzających towary na masową skalę. Robotyzacja tych procesów może przynieść nie tylko oszczędność czasu i pieniędzy, ale również bezpieczeństwo pracowników, którzy mogą zająć się mniej monotonnymi i obciążającymi fizycznie pracami.

We program robots to handle various types of products and pallets and quickly adapt them to new types of goods, which gives great flexibility in the process. It is possible to configure a large number of patterns on the pallet and various types of packaging.

Even before implementation, we analyze production, indicating what needs to be improved for robotization to bring the expected results. It is best to see this in a practical example, where we increased the efficiency of depalletization by 100%, provided an extensive buffer of pallets on the conveyors, quick retooling between types of products, and easily improved process efficiency.

Robots can operate at constant performance 24/7. Their repeatability reaches 99.9%, which increases the quality of goods prepared for distribution to customers

More and more manufacturing companies are having difficulty finding people to work. According to ManpowerGroup’s “Talent Shortage” report, as many as 45% of industrial production companies have problems filling positions with production workers. Investing in robotization of palletizing and depalletizing processes is a proven solution to this problem, which also brings benefits. Firstly, you create more attractive jobs (robot operator) than transferring packed goods to a pallet and vice versa. Secondly, you get rid of monotonous activities that pose a risk of long-term health loss and employee absence due to L4 layoffs.

We also offer our own experience to help in hiring the right person for the position of operator.

We create our stations based on proven and tested devices. We have quick access to spare parts thanks to our own warehouse stock and contracts signed with suppliers. The control is carried out using intuitive HMI panels, where you will gain access to the most important process data. We reduce the risk of operator errors through training in operation, as well as providing clear instructions on the operation and maintenance of stations and individual parts, and we also offer warranty service in the price. All this provides peace of mind in the event of an emergency and minimizes downtime due to failures.

For customers implementing their first robots, we offer support in preparing the process and staff.

Robotic stations and lines can be equipped with systems that monitor the entire process and report the results to production management systems (ERP, MES, SCADA, CMMS, WMS, or MRP), which allows for continuous improvement and increasing the efficiency of the process. The robot can be integrated, for example, with a barcode scanning system, vision system, or weight control, which further increases efficiency and control. We regularly integrate with production management systems on projects. The following innovative integration, in which we used our own solution, proves that we know the subject.

Innovative ERP integration for Blachotrapez – an example of Industry 4.0

We also offer extension of the automation of the palletization process with vision systems, weight control, robotic labeling, and an automatic pallet wrapping line that can be integrated with robotic palletization. Wrappers ensure faster preparation of pallets for distribution and the same film tension for each pallet, which increases safety during transport.

Automation, robotics and mechanics, as well as electrical and instrumentation installations will be designed and implemented by our engineers. In our assembly hall, where we assemble and test stations and lines, there is also an assembly room for control and power supply cabinets. In addition, we have a warranty and post-warranty service team that will take care of the solution after implementation.

01

Food industry

02

Plastics industry

03

Automotive

04

Electronic industry

05

Wood industry

06

Construction industry

07

Machinery industry

08

Airline industry

09

Distribution industry

10

Different? Ask via the form!

Send an inquiry or call +48 693 653 035. We will talk for a few minutes about the challenges you face.

Robotization of these processes brings many benefits, primarily for the peace of production itself, but also for business and operational benefits.

The robot is able to work even 24/7, enabling uninterrupted unloading and preparation of products for transport

The repeatability of the robot is 99.9%, which reduces quality problems and ensures process stability

Related to employment and non-quality product

Thanks to increased process efficiency, preceded by analysis

We design systems to be adapted to various product sizes and patterns on the pallet

Easy setup of the station and control of the most important indicators

By employing fewer employees with higher competences, you gain an attractive workplace

Thanks to fences, safety curtains, sensors, lights and separated zones

Manufacturing companies in developed countries have been investing in robotization for a long time

A more efficient palletizing, palletizing and packaging process speeds up the storage and distribution of pallets to customers

Thanks to regular suppliers, we have quick access to spare parts for our solutions. We design based on standards, so we know the shelf life of individual parts

We share knowledge by conducting training for client's staff. We also provide operating and maintenance instructions for our solutions

See case studies of customers who have trusted us.

Inżynier Sprzedaży

Send your inquiry and we will talk for a few minutes about your product and the challenges you face. No strings attached.

Paletyzacja robotem to proces automatycznego układania produktów na paletach za pomocą robota przemysłowego. Główne zastosowanie znajduje w przemyśle produkcyjnym, logistyce i centrach dystrybucyjnych.

Roboty pracują szybciej i wydajniej niż ludzie, co przekłada się na zwiększoną produktywność. Mogą pracować nieprzerwanie, bez przerw i zmęczenia, co pozwala na utrzymanie stałego tempa produkcji. To szczególnie istotne w branżach o wysokiej skali produkcji lub wymagających pracy zmianowej.

Zrobotyzowana paletyzacja znacząco redukuje ryzyko błędów ludzkich. Roboty wykonują zadania z niezwykłą precyzją i powtarzalnością, co przekłada się na wyższą jakość układania produktów na paletach. To z kolei minimalizuje ryzyko uszkodzeń towarów podczas transportu i składowania.

Aspekt bezpieczeństwa jest kolejnym ważnym argumentem. Paletyzacja często wiąże się z podnoszeniem ciężkich ładunków, co może prowadzić do urazów wśród pracowników. Roboty eliminują to ryzyko, poprawiając ogólne bezpieczeństwo w zakładzie.

W dłuższej perspektywie, mimo wysokich kosztów początkowych, zrobotyzowana paletyzacja może przynieść znaczne oszczędności. Redukcja kosztów pracy, mniejsza liczba błędów i uszkodzeń produktów oraz zwiększona wydajność przekładają się na lepsze wyniki finansowe firmy.

Wreszcie, wdrożenie zaawansowanych technologii może poprawić wizerunek firmy jako innowacyjnej i zorientowanej na przyszłość, co może być atutem w oczach klientów i partnerów biznesowych.

Zakup, instalacja i integracja systemu zrobotyzowanego to znacząca inwestycja, która może stanowić barierę dla wielu firm, szczególnie tych mniejszych lub o ograniczonych zasobach finansowych. Warto przed zainwestowaniem obliczyć oszczędności, jakie przyniesie taki system, aby zminimalizować ryzyko nierentownej inwestycji.

Wdrożenie zrobotyzowanej paletyzacji wymaga specjalistycznej wiedzy i umiejętności. Firmy muszą zainwestować w szkolenia personelu lub zatrudnić nowych specjalistów, co generuje dodatkowe koszty. Nasza firma przeprowadza takie szkolenia na koniec każdego projektu, co zapewnia sprawne wdrożenie pracowników klienta w nowe technologie. W przypadku braku wykwalifikowanej kadry pomagamy nawet w zatrudnieniu odpowiedniej osoby do obsługi stanowisk.

Innym wyzwaniem, jakie należy wymienić jest redukcja miejsc pracy, co może negatywnie wpłynąć na morale pracowników. Należy odpowiednio zaopiekować pracowników w tej zmianie. W większości przypadków nie dochodzi do redukcji, a personel przesuwany jest w inne miejsce. Automatyzacja prowadzi do zwiększenia wydajności, więc nierzadko potrzeba np. większej liczby wózków widłowych, aby przetransportować gotowe palety do miejsca składowania.

Decyzja o inwestycji w zrobotyzowaną paletyzację powinna być starannie przemyślana i dostosowana do specyfiki danej firmy, jej skali działania, rodzaju produkcji oraz długoterminowej strategii rozwoju.