Proster articles - sources of professional knowledge

Industry knowledge compiled by specialists for specialists. Benefit from the experience of our experts.

Relocation of industrial machinery and production lines

Relocation of industrial machinery and production lines – how to plan the whole process well in the company?

It will not be an abuse to say that the complexity of the process of relocating machinery or entire production lines, increases in direct proportion to the size of the objects being moved. Planning for such activities must take into account many factors, most of which influence each other.

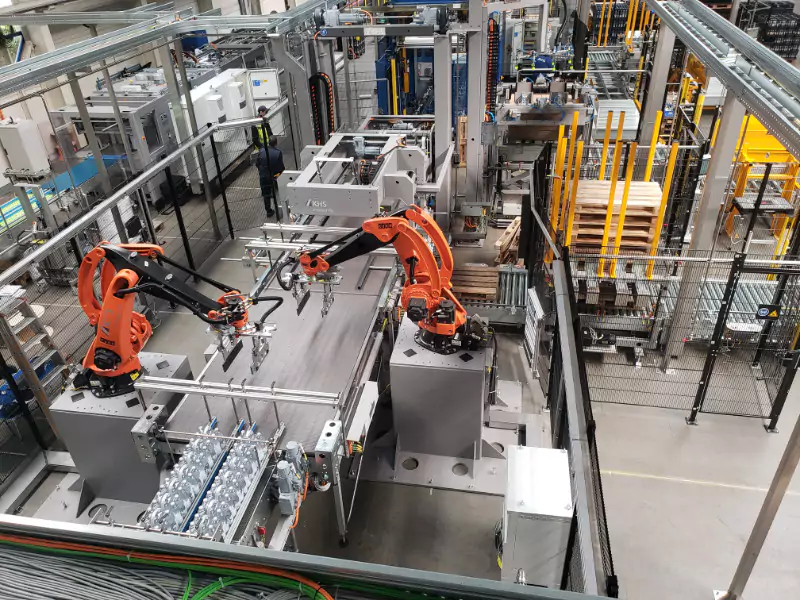

SCOPE OF WORK: For the most part, manufacturing plants are large entities that work continuously. Relocation of machinery or entire process lines often proves necessary in large enterprises. Importantly, the cost of such a task is lower than buying a new machine. Standard processes also include moving machines within a single plant. This solution does not force the necessity of stopping the work of individual positions, and the dissection of the most important activities and fitting them into a timeframe is a key element, affecting the smooth execution of the entire relocation process.

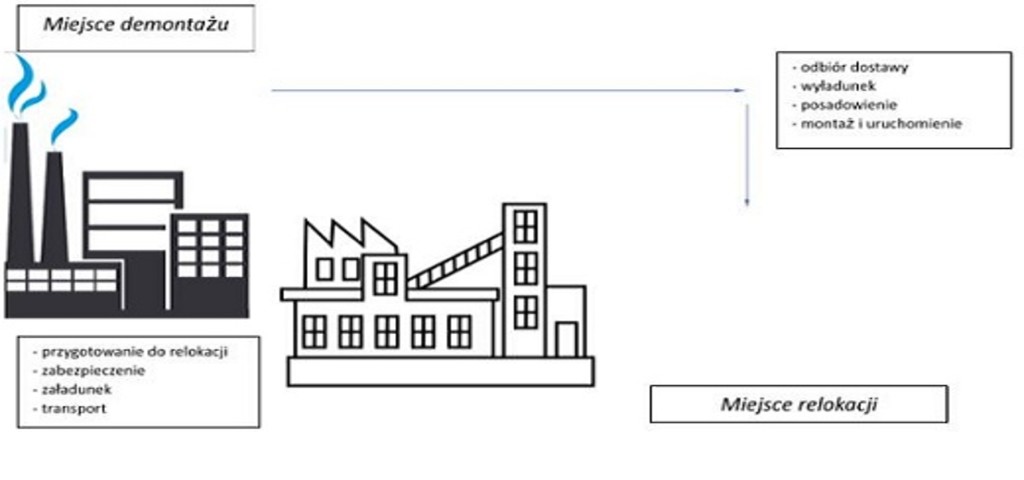

When a production line is moved, some elements of the process are expanded. This is due to the fact that the production line consists of many components. It is therefore necessary to:

- determine the dimensions of the object to be moved,

- agree on transportation logistics (exit, loading, transit, unloading, bringing the machine into the plant),

- determine the method of protection during transport (land, air, sea),

- identify the persons (entities) responsible for the various stages of the relocation process,

- identify and prepare the transportation route at the target location,

- delineate and prepare the foundation sites of the object in the target location,

- optional verification of technical documentation,

- execution (if necessary) of documentation before and during installation/disassembly and as-built documentation,

- estimation of the duration of each stage of relocation,

- estimation of the cost of the entire process.

In this context, an important role will be played by the equipment with which the relocation will be carried out – cart sets, mechanical and hydraulic jacks, lifts, etc. Their selection and operation should be provided by qualified personnel with all legally required training.