Proster articles - sources of professional knowledge

Industry knowledge compiled by specialists for specialists. Benefit from the experience of our experts.

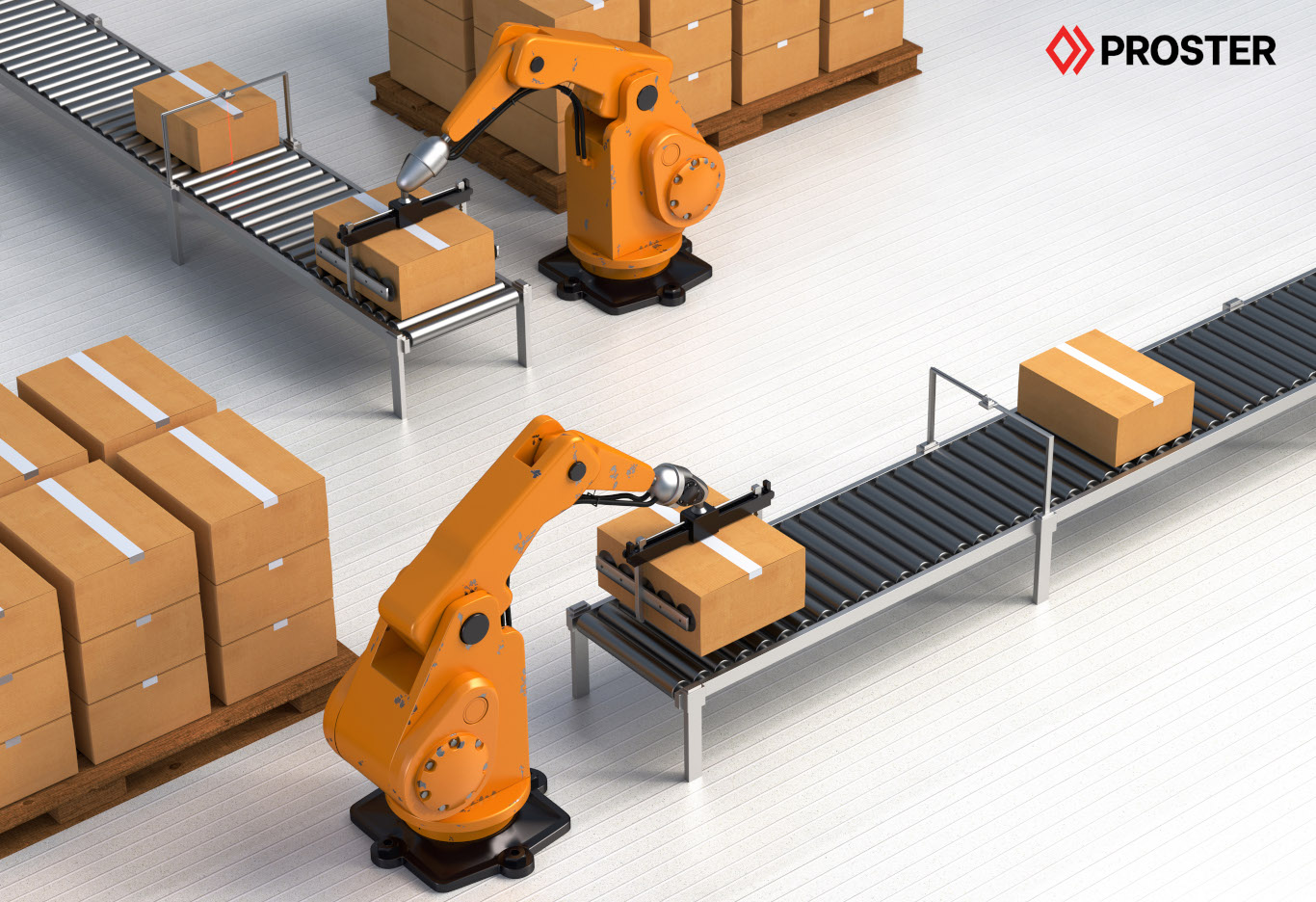

In what situations are robotic palletising systems most effective?

Palletizing is a process in which finished products such as cartons or bags are placed on a pallet in the most ergonomic way possible. Automating this process brings with it a whole host of benefits for the factory's employees, but most importantly for the business.

From this point of view, the primary benefit of introducing palletisation systems is occupational health and safety for workers involved in the production process. They work in more comfortable conditions, as they are not exposed to factors such as high or low temperatures (food industry), dust (steel mills) or the need to maintain sterile production conditions (pharmacy). Robots also have the advantage of being able to work 24 hours a day without downtime or interruptions, which translates into savings for the employer while increasing production efficiency.

The second very important factor in favor of this solution is the large lifting capacities and reach of the manipulators while reducing the space taken up. They are often far greater than the capacity of human labour, which translates into better work efficiency and higher productivity. They also take up much less space than is provided for human workstations, so they will work well in small spaces. They are also characterised by greater precision and repeatability than human labor, so they provide a guarantee of adequate protection and durability of the goods after packaging.

The third factor very often pointed out by entrepreneurs is the reduction of palletisation cycle time, which at the same time translates into direct savings and increased production capacity of the plant. It is a well-known saying that ‘time is money’, and when it comes to industry, every extra second is worth its weight in gold. A shorter cycle means more profit and better utilisation of machinery, equipment, and the ability to produce more of the product in the same amount of time.

Another undeniable benefit of the introduction of robotic solutions is their adaptability to new products, which gives greater flexibility in production and relatively rapid changes in the event of, for example, dynamic growth, plant modernisation, relocation, expansion. As we know, every business values opportunities for growth, because in this case the saying that if you stand still, you are going backwards works like nowhere else.

Last but not least, a factor that greatly influences business decisions to invest in robotic palletising systems is also an image issue. And here, too, robots are part of the trend, as they offer advanced technical solutions that position the company as a modern employer, a player in the market and increase its prestige.

As we can see, robotic palletising systems will work well in a great many industries and industrial plants. It all depends on the needs that management addresses and the objectives it sets for itself. If rapid development, state-of-the-art solutions and safety are important to you – robotic palletising systems are a great choice!