Fruit and vegetable palletising and depalletising line

Increase palletising and depalletising efficiency

Free your employees from heavy activities

Free one-page with details

Complete the form and we will send you more details about the solution.

Manual palletising and depalletising can cause problems that plants face:

- injuries, sick leave

- limited pace of goods distribution on store shelves

- employment problems

- low process efficiency

- susceptibility to errors when very tired

These challenges are answered by automation, which not only increases the efficiency of the process, which allows us to prepare the pallet for distribution faster, but also reduces the dependence on staff.

Robotization for producers and distributors of the food industry

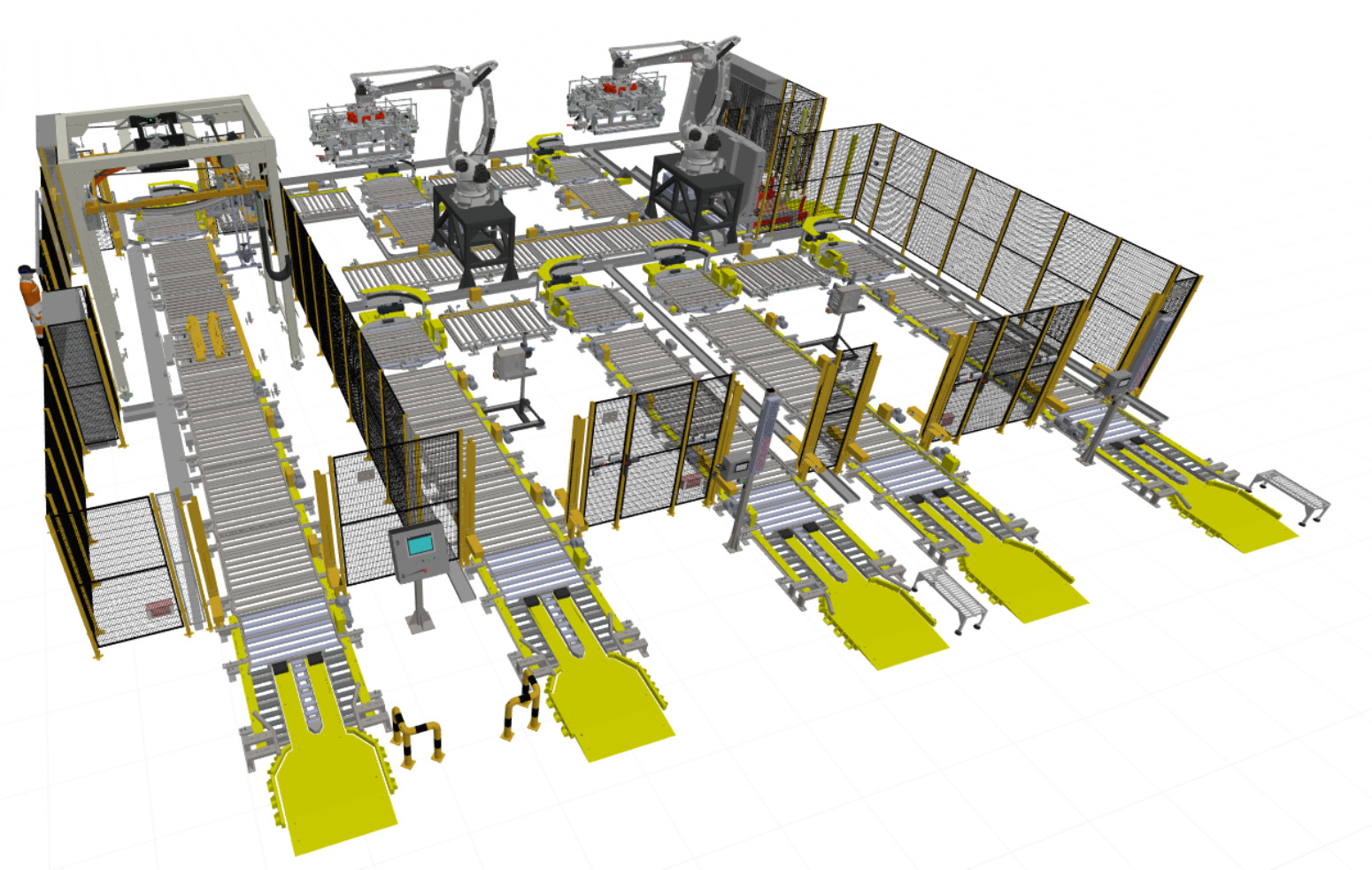

The main elements of the line for palletising and depalletising open cartons are robots and pallet transporters and turntables (adapted to low pallet trucks) designed by us especially for this type of product.

The product we created responds to the needs of producers and distributors of the food industry, especially fruits and vegetables. due to the robot gripper adapted to open boxes. Such grippers are designed for specific solutions, and each robot integrator has its own developed for specific positions. This involves design, assembly and testing, which took us almost a year in total. For you, this is a ready-made solution that we can install relatively quickly.

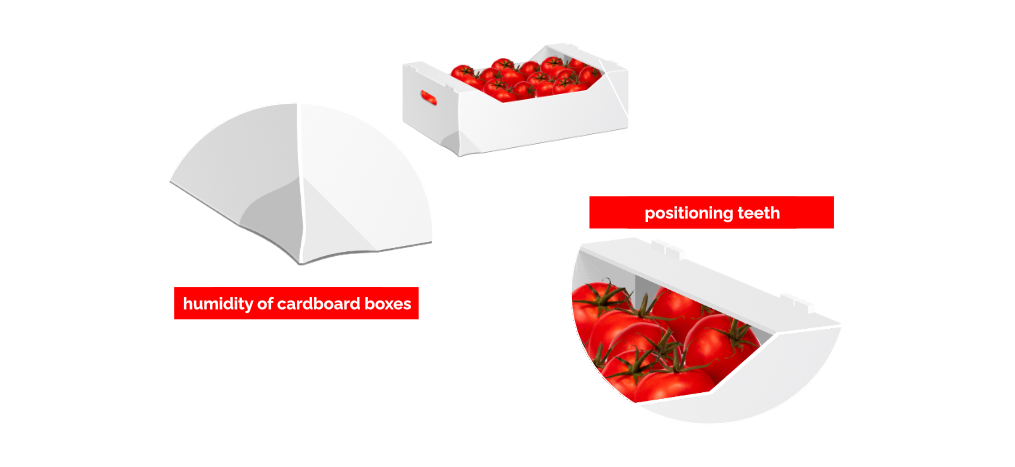

Open and closed cartons – what’s the difference?

A characteristic feature of our solution, which makes it unique, is the adaptation of the robot gripper to work with open boxes, the stiffness of which is much lower than the stiffness of closed boxes.

The cartons are often damp, which additionally reduces stiffness, and the teeth positioning the cartons on the pallet, although they improve their positioning, are an additional challenge for the robot.

Our experience of nearly 40 years in the industry allows us to say that there are no two identical implementations, so at the beginning of cooperation we will thoroughly understand your situation. Then we will prepare an optimal solution for you. A solution that brings a whole range of benefits for employees of the production plant and the business:

- physical relief – reducing sick leave and work-related injuries

- high process efficiency – the robot can work even 24/7

- more efficient distribution of goods to customers

- reducing problems with employment

- ease of configuration for new products and changeovers between existing ones

Cardboard boxes of different dimensions require a gripper to be adapted to them. We support 7 different dimensions, but if the sizes of your boxes differ, we can efficiently adapt subsequent configurations.

Some of the solutions used

Robots, automation, pneumatics

For the project we used Kawasaki robots, Siemens automation and SMC pneumatics. We use anti-corrosion components from the best manufacturers, ensuring trouble-free operation of the line for many years. We can also easily adapt to the components required by the client.

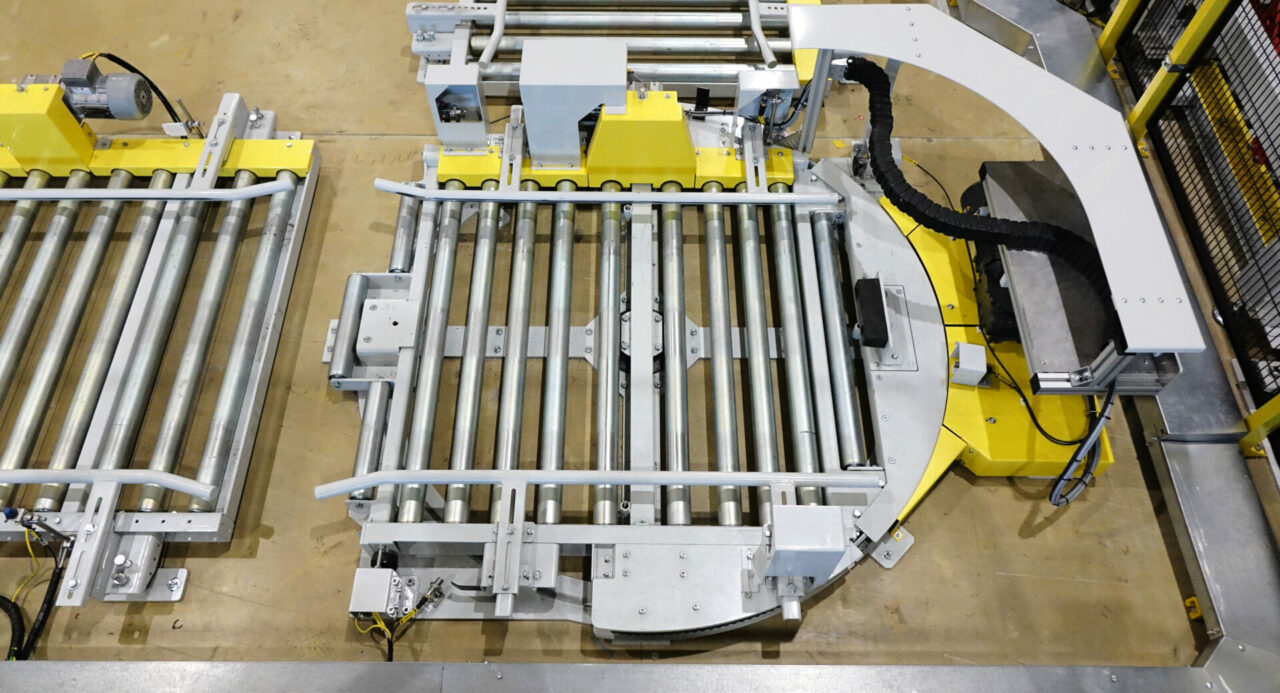

Dedicated transporters

A system of conveyors and roller turntables dedicated to low pallet trucks (loading up to 1.2 tons) allows the line to be quickly filled with the input product.

Possibility of expanding the line with additional solutions

Our partners are TOSA, QIMAROX and Signify (formerly Philips Lighting) – leaders in the production of palletizers, pallet wrappers and intelligent lighting. Below is a pallet wrapping station that increases the efficiency of the entire line.

The solution meets the conditions of INDUSTRY 4.0

We will integrate the line with any ERP system, thanks to which you will gain:

- better process control and management,

- faster response to difficulties,

- optimization of the palletization and depalletization process,

Benefits of the solution

![]()

Repeatability and quality of the process

![zwrot z inwestycji icon]()

Quick return on investment*

![ergonomia pracy ikona]()

Work ergonomics*

![wzrost wydajności]()

Performance increase*

![panel hmi2]()

Simple line control from the HMI panel*

![symulacje]()

Simulations of efficiency improvement levels

![gwarancja2]()

Guarantee*

![Serwis]()

Service*

![Części zamienne]()

Quick availability of spare parts*

*more information on the one-page

On the one-page you will find more information about:

line efficiency

estimated payback period

starting the line

our palletising and depalletising implementations

warranty and post-warranty service

possible expansion of the solution

availability of spare parts

Free one-page with details

Complete the form and we will send you more details about the solution.