Achieving ambitious objectives requires an ambitious partner

Our mission is to use innovative technology in order to improve Partners' operations. Pioneering solutions, original designs also for machinery and equipment, the highest quality standards - these are just additions.

Comprehensive cooperation

What sets us apart is the comprehensiveness of our services. From expert consultancy to implementation. Often completed before the deadline. Never completed after the deadline.

Dedicated solutions

Two identical implementations do not exist, so we get to know your situation thoroughly at the start of the cooperation. And then we will prepare a solution. Optimised specifically to your requirements.

Increased efficiency

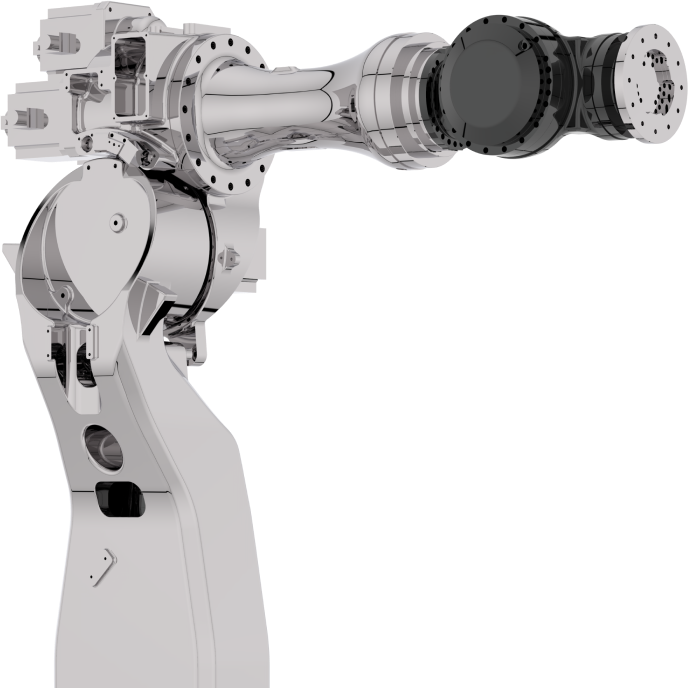

Innovative technologies improve business efficiency. We effectively use only the best technological innovations available.

Proster's greatest advantage is our experts who take on your challenge. And they will achieve ambitious objectives.

If you are interested in a longer-term cooperation, treat honesty as a prime feature

Trust can be built on honesty

in business relations, this is fundamental for us.

This is why we are uncompromising when it comes to quality, offering only certified solutions. We will tell truth, even if it is not pleasant to hear. Because we are a trustworthy partner for long-term cooperation.

Business partners

about our colaboration

The latest technology does not provide everything

Innovative solutions provide benefits. We are obliged to calculate their value for you at the beginning of the cooperation.

Partner relationships will provide you with additional benefits.

-

Timeliness and full control

We operate without delay and stick to the budget that has been agreed in advance. We stick to agreed deadlines. In the best case scenario, we finish before the deadline. With reports provided in real time, you can see the pace of our work. You will be able to control everything in real time.

-

Comprehensive consultancy

You can count on our consultancy not only during the design phase, but also during implementation when complications arise. We are also at your disposal after the completion of the project.

-

Our experts, our logistics

We have created our Dream Team of specialists, which we have been caring for for years. These specialists will work for you. Transport and procurement issues will be assumed by our logistics.

-

We provide the highest quality for you

We pursue each project using the latest technology and materials from renowned brands. So you gain the certainty that the implementation of your project will be of the highest quality.

-

Time saving

We have become a global market leader in electrical engineering, automation, robotics and industrial mechanics over more than 35 years. You can rely on our comprehensive recommendations and save time to develop your own solutions.

-

Beyond your expectations

Our engineers are innovators. For projects conducted by our engineers, the priority is to achieve the targets you have established. If possible, we attempt to exceed the established targets. So that you can achieve more.

Talk to an advisor

Send your inquiry and we will talk for a few minutes about your needs.

You can count on our reliability

To start a long-term collaboration in such crucial areas, your partner must be reliable.

And this can be expressed in numbers.

35

years in the industry passed for us in 2020.

170

employees, who are our greatest strength

5200

We have carried out projects on five continents

12

industries for which we have comprehensive solutions

Within your reach:

Technological guide

Download and benefit from knowledge you won’t find on other industry portals.

Because we developed this guide based on our technological experience. Accumulated over nearly four decades of progress Proster.

Practical applications of innovative technologies

Learn more about the details of our implementations.

See case studies of customers who have trusted us.

We are Proster

We are a global industry leader. This has been achieved through hard workand unrelenting determination.

What makes our business distinctive from the competition:

We have been in the industry for years. And we intend to remain in industry for the next few years.

We completed 100% of the projects. Within more than 35 years.

We share our knowledge and protect you from potential risks.

We support the customer at every stage and in solving any problem.

Your needs

- our solutions

Let’s meet for a free consultation

in a convenient online format and talk about the challenges you face.

Even if they are not yet fully specified.