Robotic Labeling Cell

At PROSTER we provide:

możliwe dostosowanie do różnych wymiarów etykiet oraz rodzajów opakowań i palet

Project and Integration

Installation

Launch

Training

Guarantee

Service

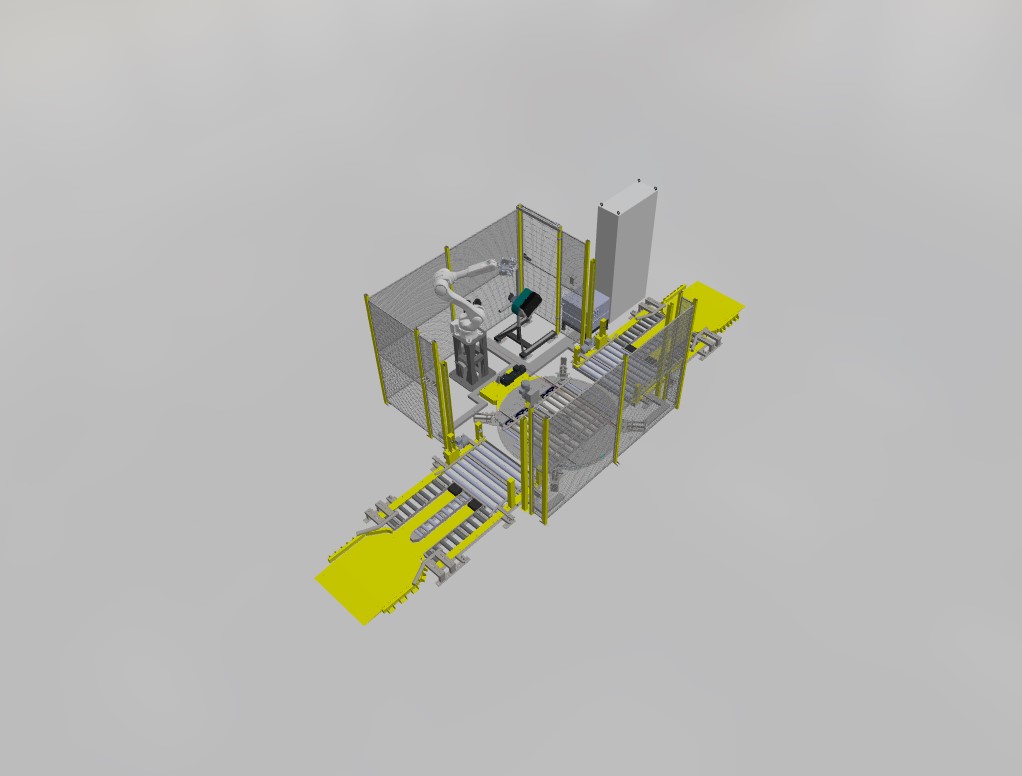

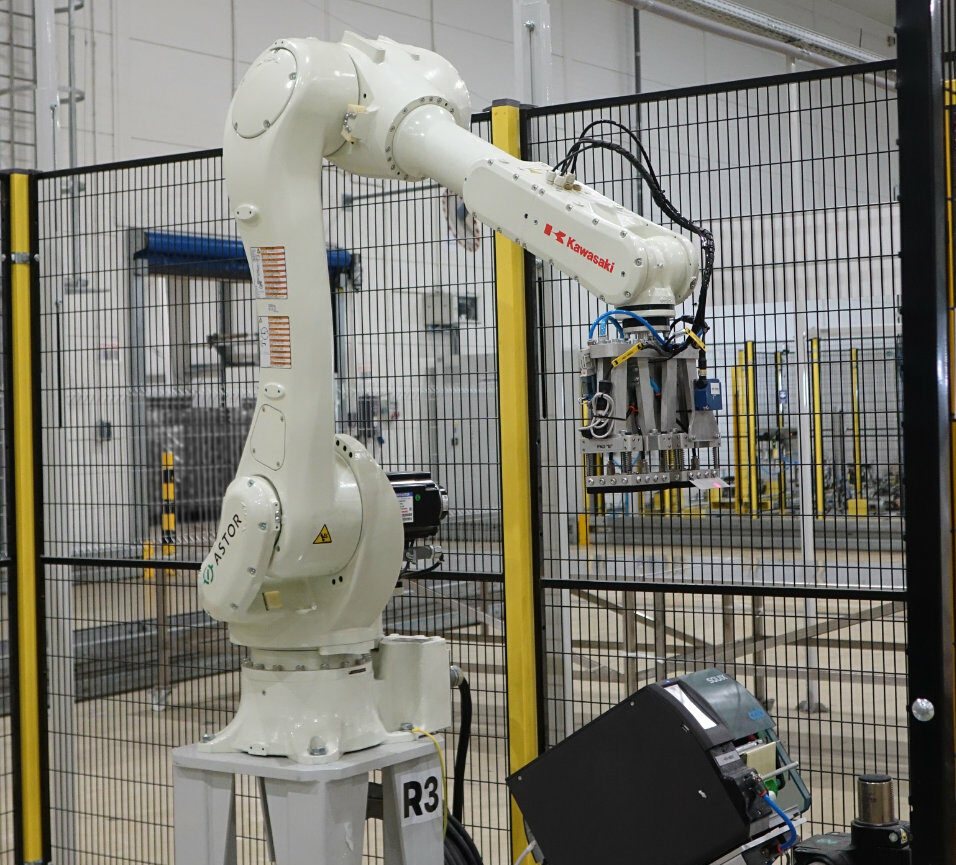

Robotic labeling is the process of applying product labels to collective packaging using an industrial robot.

Description of the cell’s operation: In the initial stage, the operator scans the collective label using a hand-held barcode scanner. The received product code is sent to the client’s superior system, which returns detailed data about the pallet. After scanning, the pallet is automatically transported to the station and labels are added to the packaging. The truck operator collects the taped pallet and passes it on to further processes.

Characteristic:

The robot’s efficiency is 17 labels per minute. For example, a pallet with 7 layers of cardboard, 8 pieces on each layer, glued on both sides, will be ready in about 210 seconds (adding the rotation of the pallet on the turntable).

- Two labels applied in one robot cycle

- Hand-held scanner of collective labels for introduced pallets

- The station is adapted to introduce pallets on low-level trolleys, thanks to dedicated conveyors and turntables

- The turntable allows for proper orientation of the pallet in relation to the industrial robot

- We integrate the station with any production management system

Stanowiska automatycznego etykietowania oferujemy razem z montażem i gwarancją.

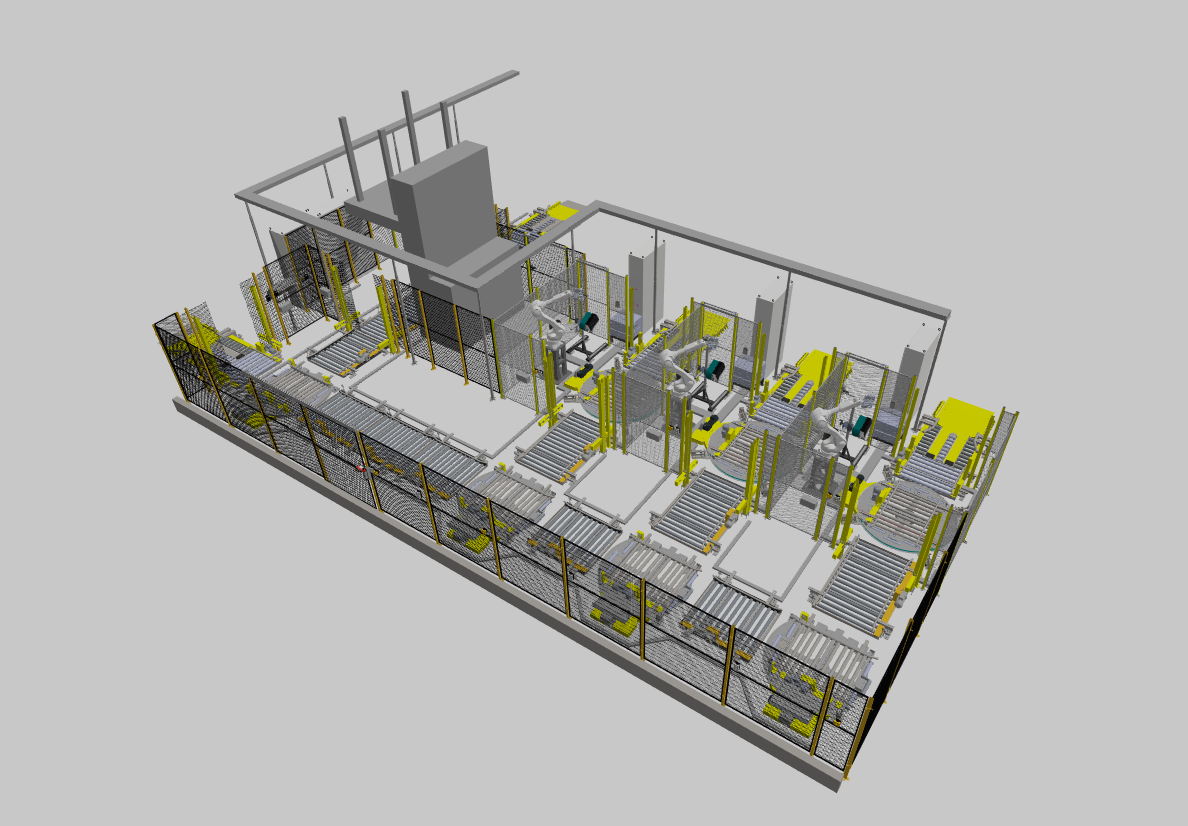

The labeling system can also be expanded with a series of conveyors and turntables, which enables pallet transport and integration with devices preparing the pallet for the target customer. Such devices may include, among others: automatic wrapping machines or strapping machines, which can be equipped with automatic corner applicators that stabilize and protect the pallet. See the system of 3 labeling robots + stripers in the photo gallery.

We offer automatic labeling stations with assembly and warranty.

Talk to an advisor

Send an inquiry or call +48 693 653 035. We will talk for a few minutes about the challenges you face.