Stretch film roll packing and palletising line

Description of our Partner's situation and problem

Efekt Plus Film Production Plant is a Polish, family-owned company whose production capacity currently stands at around 165,000 tons of stretch film per year. For the new production facility, our partner needed a line for packing

and palletization of stretch film rolls. Among the biggest challenges of this project were:

- large number of product formats

- over a dozen package sizes

- multiple palletizing schemes

- very high line efficiency

- ease of changeover

- limiting the operation of the entire line to one person

Proster Solutions

We divided the new stretch film roll packing and palletising line into seven zones. One operation takes place in each zone, starting with the collection of the wound stretch film rolls from the machine. The next step is to check the weight of the product, followed by packaging, labeling, palletising and picking up from the palletising areas for transfer to the corner application station.

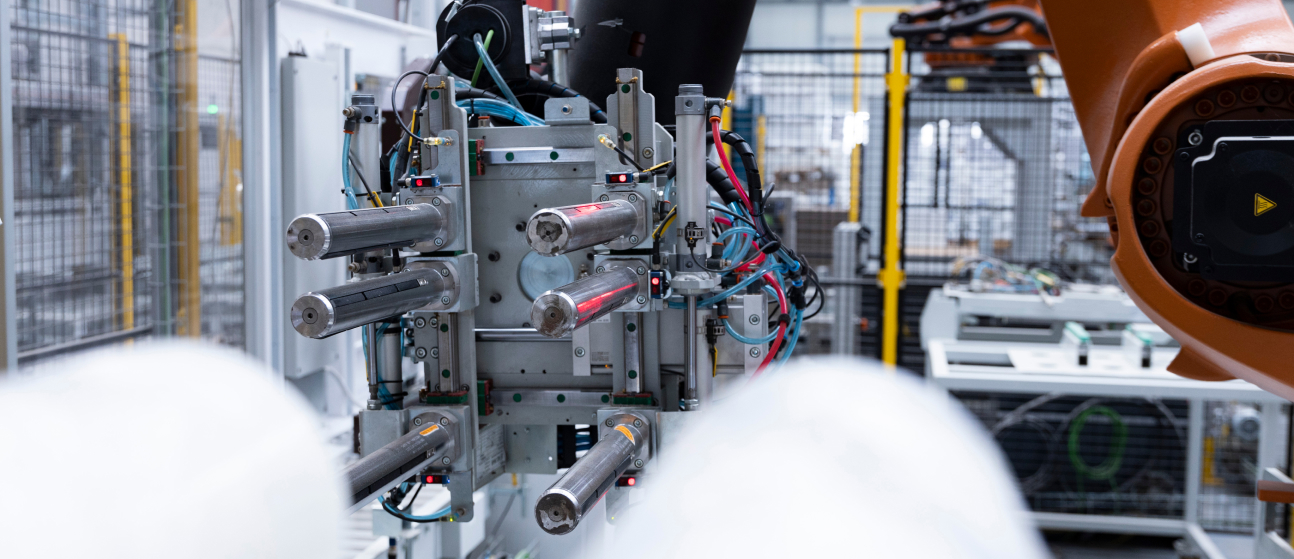

Robotised workstations

In addition, the line we designed features a robotised workstation for forming and feeding cartons to the line. This is complemented by a machine that closes the packed cartons and an automatic pallet feeding system, which consists of a mobile cart and three pallet storages. Each such storage unit handles up to four types of pallets.

Implementation process

of the project

The project took nearly 18 months to complete. During this period, we carried out design work and simulations of the fields of mechanics, automation and robotics. We manufactured the mechanical components and the power and control switchgear for the new line.

After the production stage, we tested two key robotised stations for the line (for packing rolls into cartons and for palletizing finished cartons with rolls or large-diameter rolls themselves)

on our assembly hall with the participation of the Partner’s employees.

In the next stage, after approval of our solutions, we transported the entire line to the newly built production hall of Efekt Plus, where we carried out assembly and commissioning.

The automated packing and palletising line allows our production lines to reach their full capacity. All activities, requiring physical labour are performed by appropriate robots, ensuring safety and ergonomics for production line operators.

Deputy Director for Production at Efekt Plus

Benefits for our

Partner

The stretch film roll packing and palletising line designed and built by us has provided Efekt Plus with tangible benefits.

-

Improving logistics

and increasing the safety of products in onward transportation.

-

Standardisation of product packaging

on pallets includes any type of stretch film manufactured by the Partner.

Talk to an advisor

Send an inquiry or call +48 513 221 627. We will talk for a few minutes about the challenges you face.