Prefabrication of control cabinets and connection of machines for film production

Project

SML is a technologically advanced manufacturer of top-quality film extrusion lines, located at the gateway to the picturesque Salzkammergut region in Upper Austria. The company manufactures film machines, PET containers for beverages and food products, and pharmaceuticals.

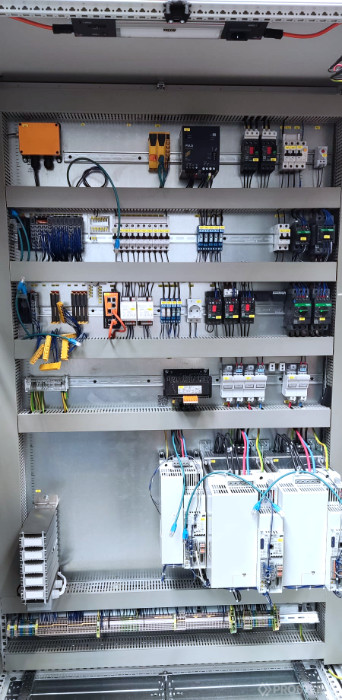

Project: Prefabrication of electrical switchboards and control cabinets and electrical connection of film machines

Project location: Austria

Scope of electrical work of machines

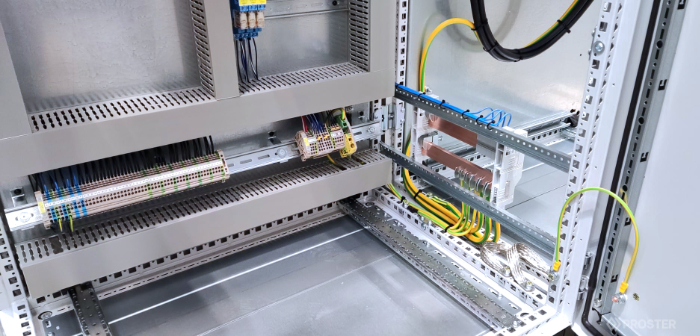

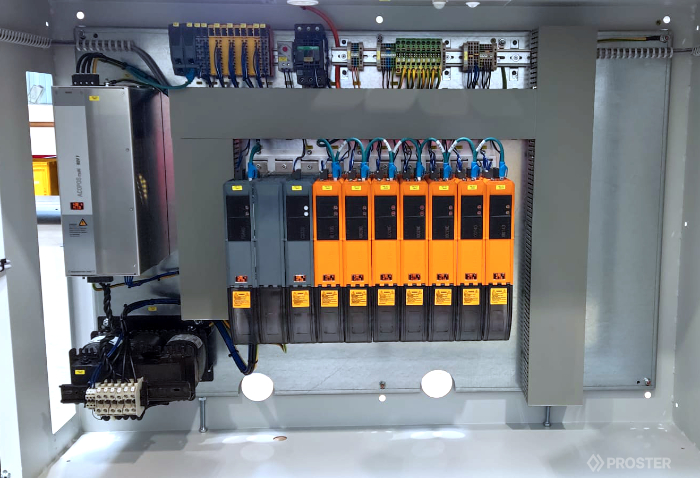

The first PROSTER team carried out work related to the prefabrication of control cabinets, complex control containers, operator panels, object cabinets and mounting plates.

Our work consisted of preparing a project tailored to the client, and therefore the country of implementation. The selection of cables is carried out in accordance with the standards and guidelines of the country to which the machine is sent. Based on the technical documentation, we selected electrical and automation components for the cabinets, then we assembled the components and made electrical connections.

The second PROSTER team carried out work directly at the construction of extrusion lines. This task required particularly high competences and experience with regard to the different processes at extrusion lines. The work consisted of wiring and connecting all devices located at the line. We made plugs, cassettes, and control panels, laid power cables and control cables (in specific standards), and also connected all control cabinets.

The work was carried out in cooperation with mechatronics engineers [technicians] from SML and ended with test runs at the machines.

Project's challenges

The most important challenges at the implementation of the project were the knowledge of the technology at extrusion lines and its adaptation to the requirements of different individual customers.

SML’s customers come from various countries, which makes it necessary to use different standards and guidelines for connecting cables.

The wiring and connection work of all the devices at the machines required extensive knowledge and experience in the assembly of specific machines.

Benefits for our Partner

-

Knowledge and experience of technical issues of machines and industry

ensured safe and secure installation and connection of cables

-

High quality of work performed

ensures continuous operation of machines

-

Working with a reliable partner

confirmed by the ISO 9001 quality management system certificate (check the footer)

-

Timeliness of work

helped to avoid delays in shipping machines to customers