Increased efficiency of palletising and depalletising of fruit and vegetables for Amplus

Project

Amplus is a family company producing and distributing fruit and vegetables to the shelves of Polish stores. The company employs almost half a thousand employees, and in 2021 it generated revenue of over PLN 1 billion.

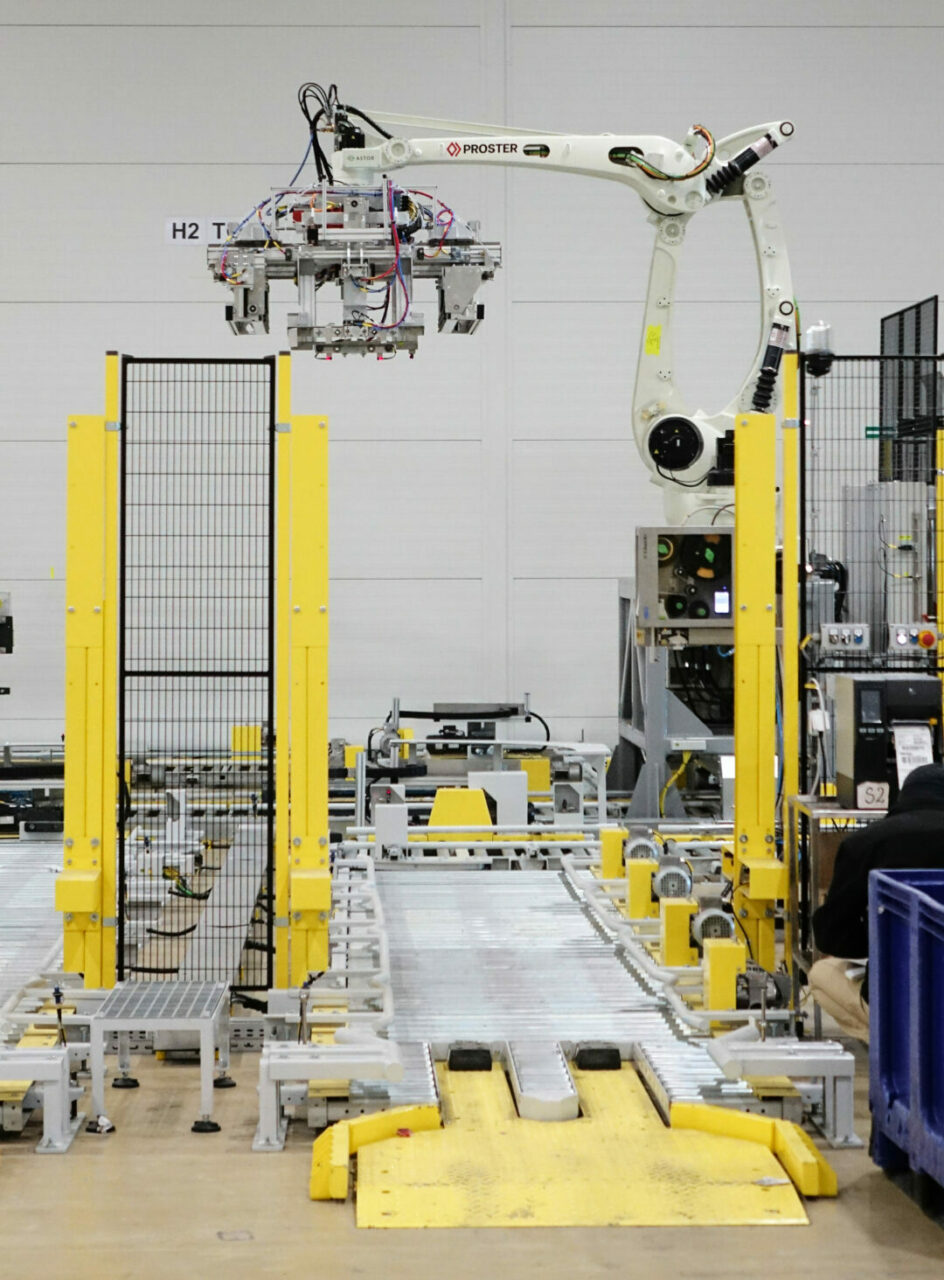

Robotisation of the palletising and depalletising process for our partner included comprehensive – consulting, design, assembly and commissioning of the line, as well as staff training, integration with the management system and expansion with an automatic pallet wrapping machine. The most important challenges associated with this project were:

- Design of a special gripper adapted to the product,

- Low pallet transport,

- A wide range of cardboard references,

- Combination of the depalletization and palletization process,

- High line efficiency,

- Communication with the superior system,

- Wrapping the pallet with stretch foil (while maintaining high air access to fruit and vegetables).

The aim of the line was to reduce the number of cardboard layers on a pallet (depalletization), while palletizing the product from the removed layers. Robotisation of these processes allows for the reduction of manual handling of heavy boxes weighing up to 20 kg, which reduces health problems for staff. In addition, it improves the distribution of pallets to our partner’s customers.

Description of the palletising and depalletising line

Processes inside the line are fully automatic. The depalletising and palletising procedure begins when the pallets appear on the appropriate conveyors. Newly stacked pallets are directed to an automatic pallet wrapper, from where they are transported for collection.

Pallet entry zones

The depalletising process takes place in two zones, designed in a modular way. In the product pallet entry section, the operator unpacks the pallet to the required height, marked with an LED marker located next to the line entrance. The operator then scans the product’s label. Thanks to this, information about the introduced product is transferred to the robot and the labeling machine, which results in the adjustment of the appropriate robot work program and label printing. After placing the pallets on the input conveyors, the operator confirms that the line is ready for operation using a button on the control pendant. The pallet entry zone is a place where pallets are checked for quality and prepared for unpacking.

Depalletising and palletising zones

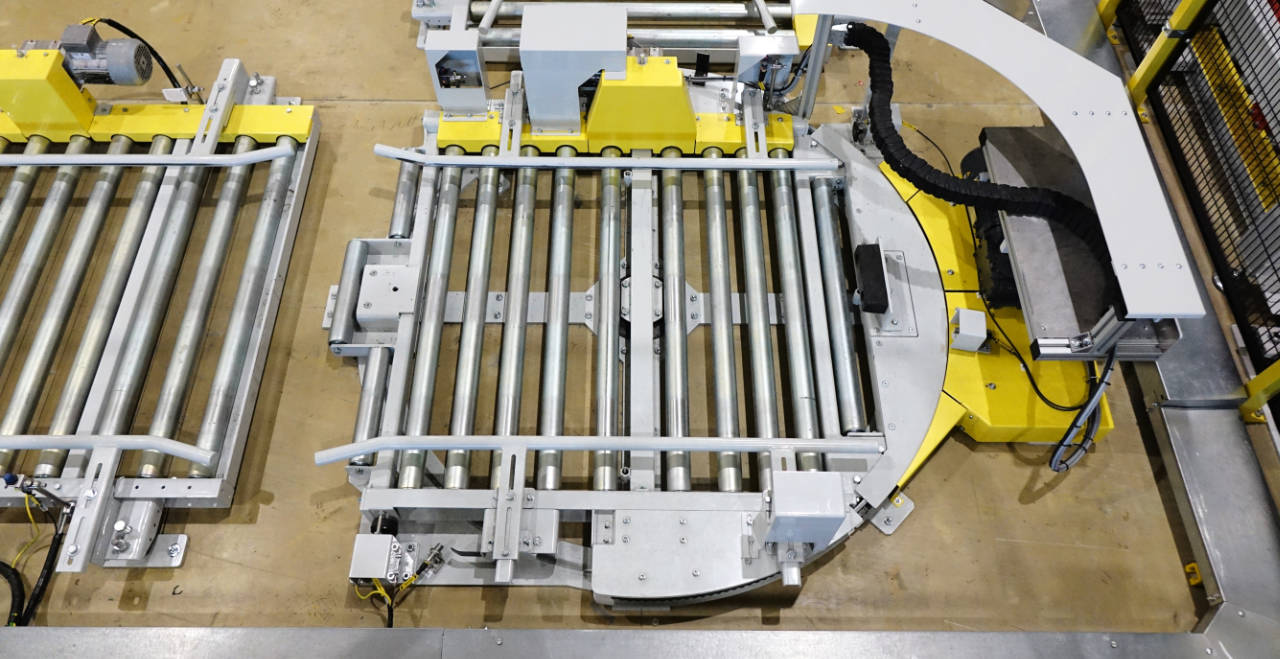

Entry to the zone is automatic, on roller conveyors and turntables. One depalletising zone allows for buffering from one to five pallets on the conveyors.

The line has been designed in such a way that the depalletised product is automatically placed on a new pallet (palletized).

New pallets are dispensed automatically by the machine, which is able to store up to 12 pieces and then dispense them individually to the line in response to the demand reported by the control system.

Pallet wrapping and receiving area

Stacks of finished pallets with the product, after the palletising process, are transported via a system of conveyors and turntables to the wrapping machine, and a label is automatically applied along the way. Thanks to automatic wrapping, pallets are quickly and reproducibly secured for distribution to customers.

The working area of the entire line is secured with a protective fence. The entrance zones to the line are protected by a system of light curtains with a muting option. Thanks to this, the highest safety standards of this type of solutions are maintained.

Proster solutions

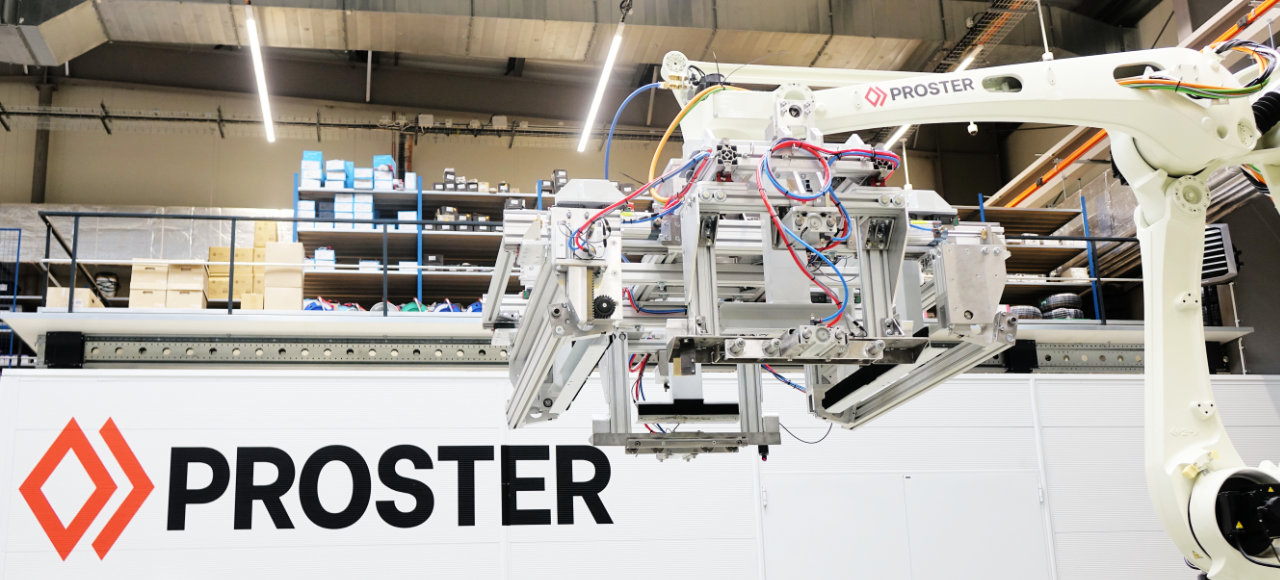

The most important stage of our team’s work was the design and implementation of production of a gripper that is able to pick up the entire layer of cardboard boxes and put them aside, creating even stacks. The cartons are open at the top, which is unusual packaging for this type of automation and was quite a challenge. This type of packaging is less stable than closed cartons, and the fruit and vegetables it contains make it moist, further complicating the process. In addition, such packaging contains positioning teeth, improving the stability of the entire pallet with the product, but forcing the robot to work with extreme precision.

The robot’s gripper consists of a set of movable side bands that allow for repeated gripping of a package of cartons and proper positioning on a new layer. The positions of the side bands are adjusted using a servo drive, which allows for smooth changeover of the gripper depending on the reference and adjustment of the pressing force of the cartons. An additional function is to move the empty pallet to the palletising zone.

The set of conveyors and turntables was designed specifically to meet the partner’s requirements. They allow pallets to be transported at a height of 100 mm from the floor, making it possible to use low pallet trucks.

Then, the process of wrapping the pallet with stretch foil required the design of a special lift that allows integration with the low conveyor system without the need to interfere with the floor. The lift is able to lift a pallet weighing up to one tonne by a height of 80 mm.

Implementation of the project

We have design and installation teams in the fields of automation, robotics, mechanics, and electric engineering (including prefabrication of control cabinets). Such comprehensive and well-coordinated teams enable the implementation of production and technological line projects from beginning to end. It was no different in this case. All work was carried out by Proster teams, supervised by leaders and project managers.

Even before implementation, thanks to our experience with this type of solutions, we advised the partner on process improvements that would help optimize the operation of the line.

The construction stage included, among other things, designing the robot’s gripper, dedicated conveyors and roller turntables. In the meantime, automation and robotics engineers were working on programming the line controls and industrial robots to work with the product.

After carrying out construction works and mechanical and electrical assembly of individual devices, we carried out tests of the line and key automation elements. We built our gripper and tested it for durability and performance. This allowed us to improve it to take full advantage of its functionality.

Tests in the presence of a partner

A shortened version of the station was created in our assembly hall, thanks to which we were able to configure and test the control programs at an early stage. It also allowed us to carry out functionality and performance tests of the lines, where our partner’s representatives were present.

After the tests were approved, mechanical and electrical assembly took place at the Amplus plant. After launching the entire line, our programmers focused on optimizing and achieving full operating efficiency.

The last stage of the project was to provide line operation training for Amplus staff, hand over the line to the partner (together with instructions for operation and maintenance of machines and devices) and support with production assistance.

Challenges

Cartons open at the top are an unusual product in automatic palletising, which requires extraordinary precision. This type of packaging is less stable than closed cartons, and the fruit and vegetables it contains make it moist, further complicating the process. In addition, such packaging contains positioning teeth, improving the stability of the entire pallet with the product, but forcing the robot to work with extreme precision. We solved this challenge by designing an advanced robot gripper dedicated to this product.

Another requirement was the entry of pallets using low pallet trucks. For this purpose, we have designed a set of conveyors and turntables at a height of 100 mm from the floor.

240

pallets / shift is the average line efficiency

Benefits for our partner

The fruit and vegetable palletization and depalletization line we designed and manufactured provided Amplus with measurable benefits.

-

Process automation

responds to the increase in product demand on the market, following the trend of industry 4.0 and the increase in processing capacity

-

Increased process efficiency

thanks to robots that can work even 24/7

-

Reducing staff health problems

thanks to the reduction of heavy handling of boxes weighing up to 20 kg

-

Comprehensive staff training

ensures occupational health and safety during the operation of the depalletization line

-

Device operation and maintenance manuals

ensure safe use and long service life of the line

-

Process optimization consulting

helped to better prepare for a change at the plant

-

More efficient preparation for the distribution of pallets to customers

provides greater peace of mind for the partner and satisfaction of its customers

-

Greater repeatability of pallet wrapping

while ensuring adequate air circulation and safety during transport

-

PROSTER warranty and post-warranty service

guarantees quick response to the call and peace of mind in the event of a system failure

Talk to an advisor

Send an inquiry or call +48 513 221 627. We will talk for a few minutes about the challenges you face.