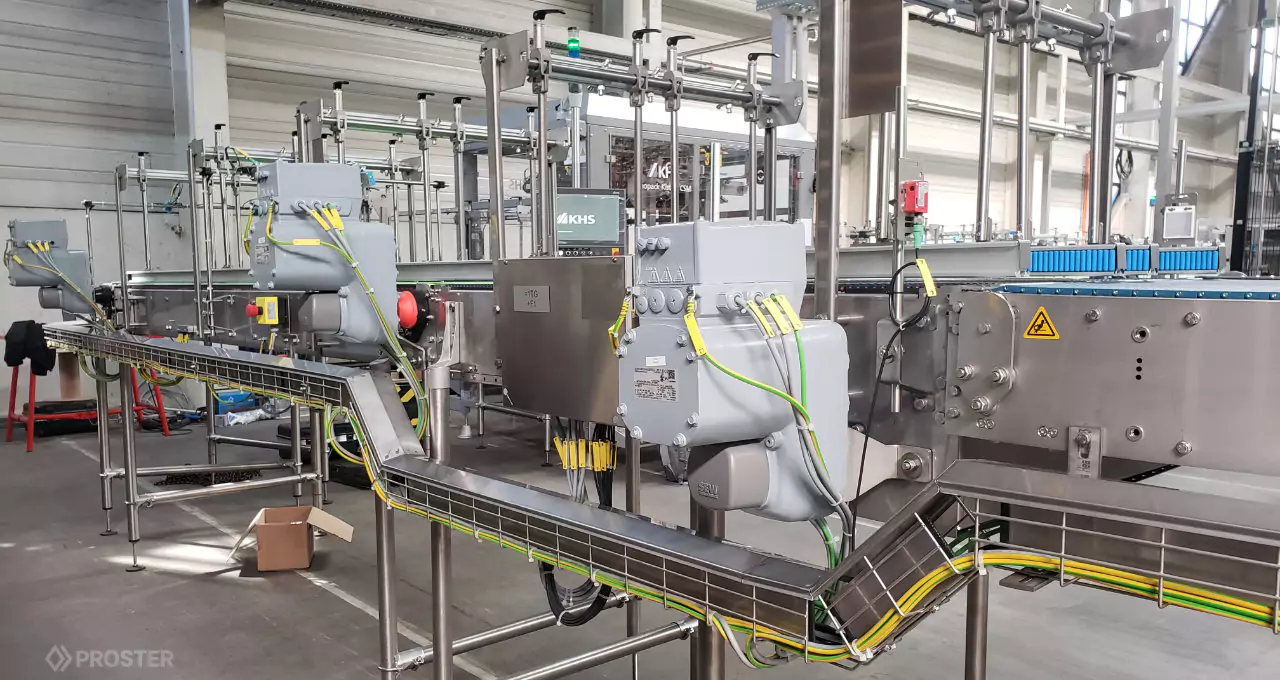

Assembly of packaging machines, palletizing machines and conveyor systems for KHS

Project

KHS Group is one of the world leaders in the production of bottling and packaging machines. With over 150 years of history, it is one of the most experienced suppliers of this type of machines on the market.

Project: Assembly of packaging machines, palletizing machines and conveyor systems

Place of project implementation: Germany

![]()

Industrial mechanics and electrics

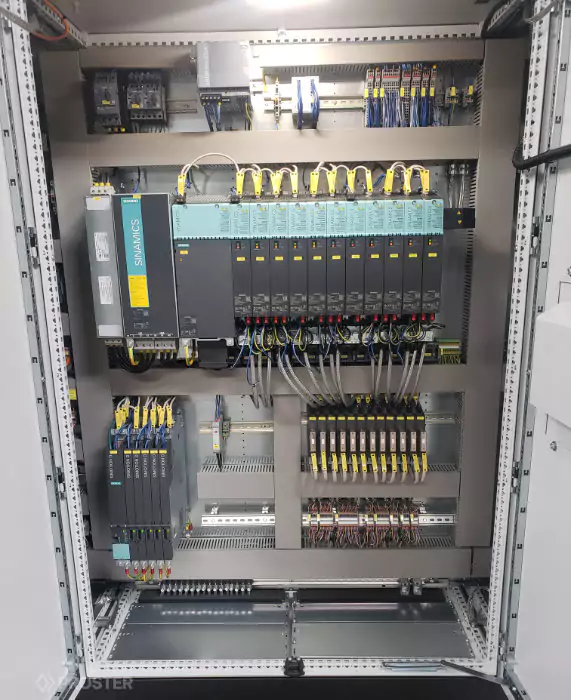

The scope of PROSTER’s work included unloading the machines from the transport, locating the machines in the plant according to the layout and full mechanical assembly of the machines. Next, the electrical installation of the machines, including laying the main cable routes and control cables and power cables, electrical connection of the machines, assembly and connection of the main switchboard and control cabinets of individual machines, as well as other elements such as HMI operating panels, safety curtains, sensors or emergency stop buttons. In addition, I/O control, inspection of the installation and documentation, as well as documentation of all changes.

The machines that were part of the assembly work were:

- Machine for wrapping the product in foil

- Machine for placing the handle

- Machine for storing and issuing pallets

- Palletizer

- Conveyor system for product packaging

- Pallet conveyor system

Benefits for our Partner

We are a partner of KHS in electrical and mechanical installations for industrial lines, hence the work is carried out with repeatable, highest quality

-

Full knowledge of the technical aspects of the machines

allowed the project to be completed on time, without any unexpected additional costs

-

Implementation with a reliable partner

we perform work confirmed by the ISO 9001 quality management system certificate (check the footer)

-

High quality of work performed, known to the partner

ensures safe assembly of production line machines and minimizes the risk of failure